D700 QUICK START MANUAL

8

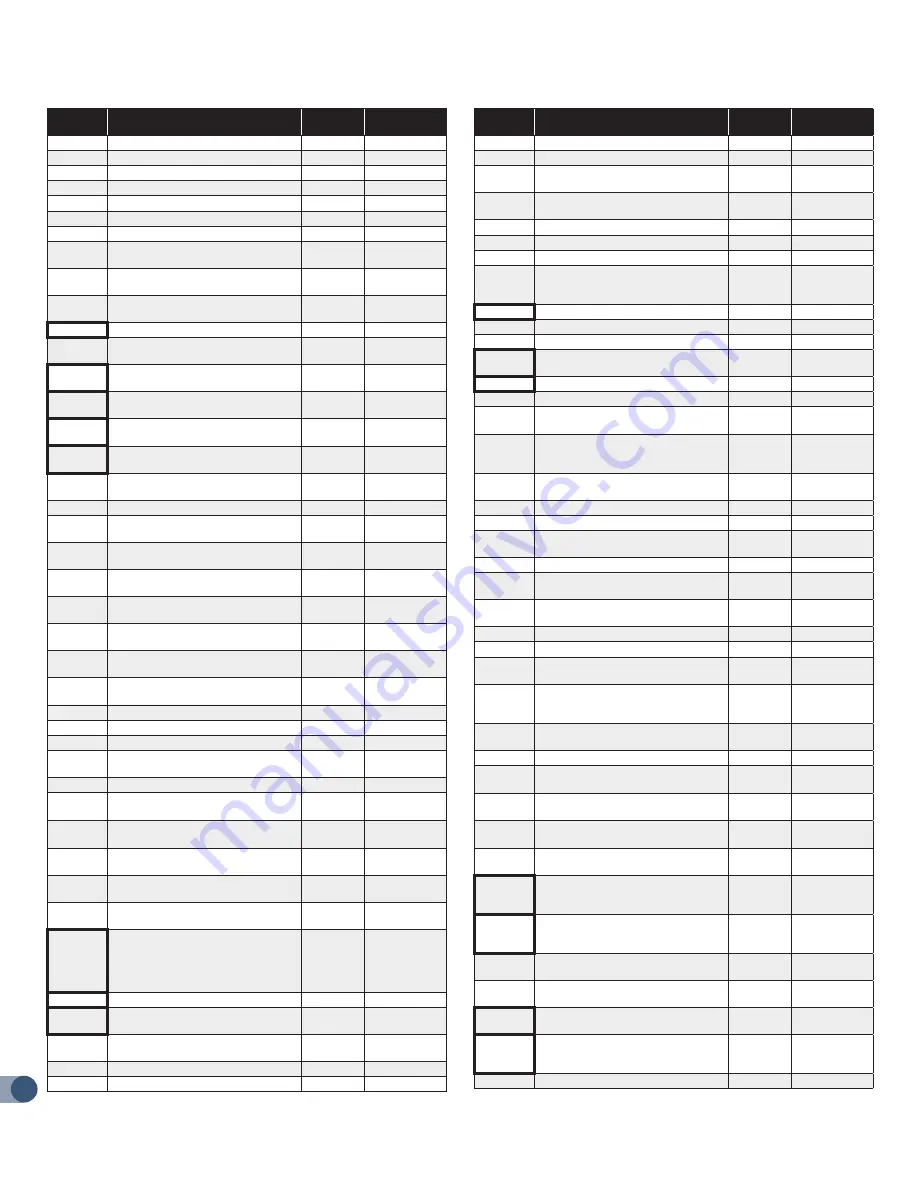

Parameter

Name

Setting

Range

Initial Value

11

DC injection brake operation time

0 to 10s

0.5s

12

DC injection brake operation voltage

0 to 30%

6/4% *3

13

Starting frequency

0 to 60Hz

0.5Hz

14

Load pattern selection

0 to 3

0

15

Jog frequency

0 to 400Hz 5Hz

16

Jog acceleration/deceleration time

0 to 3600s 0.5s

17

MRS input selection

0, 2, 4

0

18

High speed maximum frequency

120 to

400Hz

120Hz

19

Base frequency voltage

0 to 1000V,

8888, 9999 9999

20

Acceleration/deceleration reference

frequency

1 to 400Hz 60Hz

22

Stall prevention operation level

0 to 200%

150%

23

Stall prevention operation level

compensation factor at double speed

0 to 200%,

9999

9999

24

Multi-speed setting (speed 4)

0 to 400Hz,

9999

9999

25

Multi-speed setting (speed 5)

0 to 400Hz,

9999

9999

26

Multi-speed setting (speed 6)

0 to 400Hz,

9999

9999

27

Multi-speed setting (speed 7)

0 to 400Hz,

9999

9999

29

Acceleration/deceleration pattern

selection

0, 1, 2

0

30

Regenerative function selection

0, 1, 2

0

31

Frequency jump 1A

0 to 400Hz,

9999

9999

32

Frequency jump 1B

0 to 400Hz,

9999

9999

33

Frequency jump 2A

0 to 400Hz,

9999

9999

34

Frequency jump 2B

0 to 400Hz,

9999

9999

35

Frequency jump 3A

0 to 400Hz,

9999

9999

36

Frequency jump 3B

0 to 400Hz,

9999

9999

37

Speed display

0, 0.01 to

9998

0

40

RUN key rotation direction selection

0, 1

0

41

Up-to-frequency sensitivity

0 to 100%

10%

42

Output frequency detection

0 to 400Hz

6Hz

43

Output frequency detection for reverse

rotation

0 to 400Hz,

9999

9999

44

Second acceleration/deceleration time

0 to 3600s

5/10s *2

45

Second deceleration time

0 to 3600s,

9999

9999

46

Second torque boost

0 to 30%,

9999

9999

47

Second V/F (base frequency)

0 to 400Hz,

9999

9999

48

Second stall prevention operation

current

0 to 200%,

9999

9999

51

Second electronic thermal O/L relay

0 to 500A,

9999

9999

52

DU/PU main display data selection

0, 5, 8 to

12, 14, 20,

23 to 25, 52

to 55, 61,

62, 64, 100

0

55

Frequency monitoring reference

0 to 400Hz

60Hz

56

Current monitoring reference

0 to 500A

Rated inverter

current

57

Restart coasting time

0, 0.1 to 5s,

9999

9999

58

Restart cushion time

0 to 60s

1s

59

Remote function selection

0, 1, 2, 3

0

Parameter

Name

Setting

Range

Initial Value

60

Energy saving control selection

0, 9 0

0, 9 0

65

Retry selection

0 to 5

0

66

Stall prevention operation reduction

starting frequency

0 to 400Hz

60Hz

67

Number of retries at fault occurrence

0 to 10, 101

to 110

0

68

Retry waiting time

0.1 to 600s 1s

69

Retry count display erase

0

0

70

Special regenerative brake duty

0 to 30%

0%

71

Applied motor

0, 1, 3, 13,

23, 40, 43,

50, 53

0

72

PWM frequency selection

0 to 15

1

73

Analog input selection

0, 1, 10, 11

1

74

Input filter time constant

0 to 8

1

75

Reset selection/disconnected PU

detection/PU stop selection

0 to 3, 14

to 17

14

77

Parameter write selection

0, 1, 2

0

78

Reverse rotation prevention selection

0, 1, 2

0

*79

Operation mode selection

0, 1, 2, 3,

4, 6, 7

0

80

Motor capacity

0.1 to

7.5kW,

9999

9999

82

Motor excitation current

0 to 500A,

9999

9999

83

Rated motor voltage

0 to 1000V

200V/400V *5

84

Rated motor frequency

10 to 120Hz 60Hz

90

Motor constant (R1)

0 to 50Ω,

9999

9999

96

Auto tuning setting/status

0, 11, 21

0

117

PU communication station number

0 to 31 (0

to 247)

0

118

PU communication speed

48, 96, 192,

384

192

119

PU communication stop bit length

0, 1, 10, 11

1

120

PU communication parity check

0, 1, 2

2

121

Number of PU communication retries

0 to 10,

9999

1

122

PU communication check time interval

0, 0.1 to

999.8s,

9999

0

123

PU communication waiting time setting

0 to 150ms,

9999

9999

124

PU communication CR/LF selection

0, 1, 2

1

125

Terminal 2 frequency setting gain

frequency

0 to 400Hz

60Hz

126

Terminal 4 frequency setting gain

frequency

0 to 400Hz

60Hz

127

PID control automatic switchover

frequency

0 to 400Hz,

9999

9999

128

PID action selection

0, 20, 21,

40 to 43

0

129

PID proportional band

0.1 to

1000%,

9999

100%

130

PID integral time

0.1 to

3600s,

9999

1s

131

PID upper limit

0 to 100%,

9999

9999

132

PID lower limit

0 to 100%,

9999

9999

133

PID action set point

0 to 100%,

9999

9999

134

PID differential time

0.01 to

10.00s,

9999

9999

145

PU display language selection

0 to 7

1

MitsubishiElectric Automation, Inc.