English –

21

English

The control unit has a number of optional functions to enable the user to

add specific functionalities to the automation, thus personalising the prod-

uct according to special needs.

10

– AUTOMATION OPERATION ADJUSTMENT

To personalise operation of the automation, a number of functions can be

enabled or disabled, also with the option for modifications to settings as

required. The functions are:

• AUTOMATIC LEAF CLOSURE

. When this function is enabled, at the

end of the Opening manoeuvre command by the user, the control unit

automatically closes the gate again after a set time interval.

• LEAF MOVEMENT SPEED

. This function enables entry of the required

speed of the automation implemented to move the gate leaf.

• AUTOMATION SENSITIVITY TO OBSTACLES

. During a manoeuvre, if

an obstacle accidentally stops gate leaf movement (a strong gust of wind,

a vehicle, person etc.) this function promptly detects the increase in motor

stress to contract the obstacle and activates immediate total inversion of

movement. If “automatic leaf closure” is set, the control unit re-attempts

the movement a second time and on the third time, after a brief inversion,

it stops the manoeuvre permanently.

• DECELERATION MODES

. This function enables selection of the decel-

eration start point during gate leaf travel both in the Closing and Opening

phases.

Note

– This parameter is essential for guaranteeing a low impact force in

the event of impact with an obstacle in the final phase of a manoeuvre.

The values of these functions can be set according to personal require-

ments using the following procedure with a transmitter that has at least

one key already memorised on the control unit.

Note

– During this procedure, each time a key is pressed the flashing light

emits one flash.

01.

Press and hold the keys “

T1

” and “

T2

” simultaneously on the trans-

mitter for at least

5 seconds

, after which release.

The two leds (green and red) on the Control unit flash to indicate entry

to function programming mode

(the leds continue to flash throughout

the procedure)

.

02.

Press and hold a transmitter key (already memorised on that of the

control unit) for at least

1 second

(the green Led emits one flash)

.

03.

Then select one of the four functions available and on the transmitter

press the key associated with the function for at least 1 second

(the

green Led emits one flash)

:

• Automatic leaf closure

= (press key “

T1

”)

• Leaf movement speed

= (press key “

T2

”)

• Leaf sensitivity to obstacles

= (press key “

T3

”)

• Leaf deceleration points

= (press key “

T4

”)

04.

Lastly, refer to

Table 3

, select the required value in correspondence

with the selected function and on the transmitter press the key asso-

ciated with the selected value for at least

1 second

(the green and

red Leds emit one confirmation flash)

.

Notes to

Table 3

:

– The Table states the values available for each of the 4 special functions

and the corresponding key to be pressed on the transmitter for selection

of the specific value.

– The factory settings are highlighted in grey.

(

*

) –

The “

High

” parameter means that the gate can detect obstacles that

generate a low force, such as a strong gust of wind.

–

The “

Low

” parameter means that the gate can detect obstacles that

generate a high force, such as a stationary car.

– In the event of a power failure, on restoral of power the first manoeuvre

command will be executed at low speed, regardless of the type of speed set.

11

– MEMORISING A NEW TRANSMITTER WITH

PROCEDURE IN THE VICINITY OF THE CONTROL

UNIT [with a transmitter already memorised]

A NEW transmitter can be memorised in the control unit memory without

acting directly on key

P1

of the control unit, but by simply working within

its reception range. To use this procedure, an OLD transmitter, previously

memorised and operative, is required. This enables memorisation of the

same function of a specific key on the OLD transmitter on any key of the

NEW transmitter.

Warnings:

– The procedure must be performed within the reception range of

the receiver (maximum 10-20 m from receiver).

–

The procedure memorises a single key of the new transmitter. To

memorise other keys, repeat the same procedure

01.

On the NEW transmitter, press and hold the key to be memorised for

at least

5 seconds

and then release.

02.

On the OLD transmitter, slowly press the control key to be memo-

rised on the other transmitter

3 times

.

03.

On the NEW transmitter, press the same key pressed in point 01

once

.

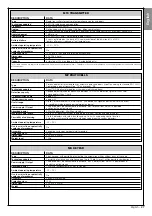

ADJUSTMENTS AND OTHER OPTIONAL FUNCTIONS

TABLE 3

AUTOMATIC LEAF CLOSURE

No closure —> (press key “

T1

”)

Closure after 15 seconds —> (press key “

T2

”)

Closure after 30 seconds —> (press key “

T3

”)

Closure after 60 seconds —> (press key “

T4

”)

LEAF MOVEMENT SPEED

Low

—> (press key “

T1

”)

Medium low

—> (press key “

T2

”)

Medium high

—> (press key “

T3

”)

High

—> (press key “

T4

”)

AUTOMATION SENSITIVITY TO OBSTACLES

High

(

*

) —> (press key “

T1

”)

Medium high

—> (press key “

T2

”)

Medium low

—> (press key “

T3

”)

Low

(

*

) —> (press key “

T4

”)

DECELERATION MODES

20 cm in

Opening

/ 20 cm in

Closing

low impact speed

—> (press key “

T1

”)

20 cm in

Opening

/ 70 cm in

Closing

low impact speed

—> (press key “

T2

”)

70 cm in

Opening

/ 70 cm in

Closing

low impact speed

—> (press key “

T3

”)

70 cm in

Opening

/ 70 cm in

Closing

very low impact speed

—> (press key “

T4

”)