8

– English

English

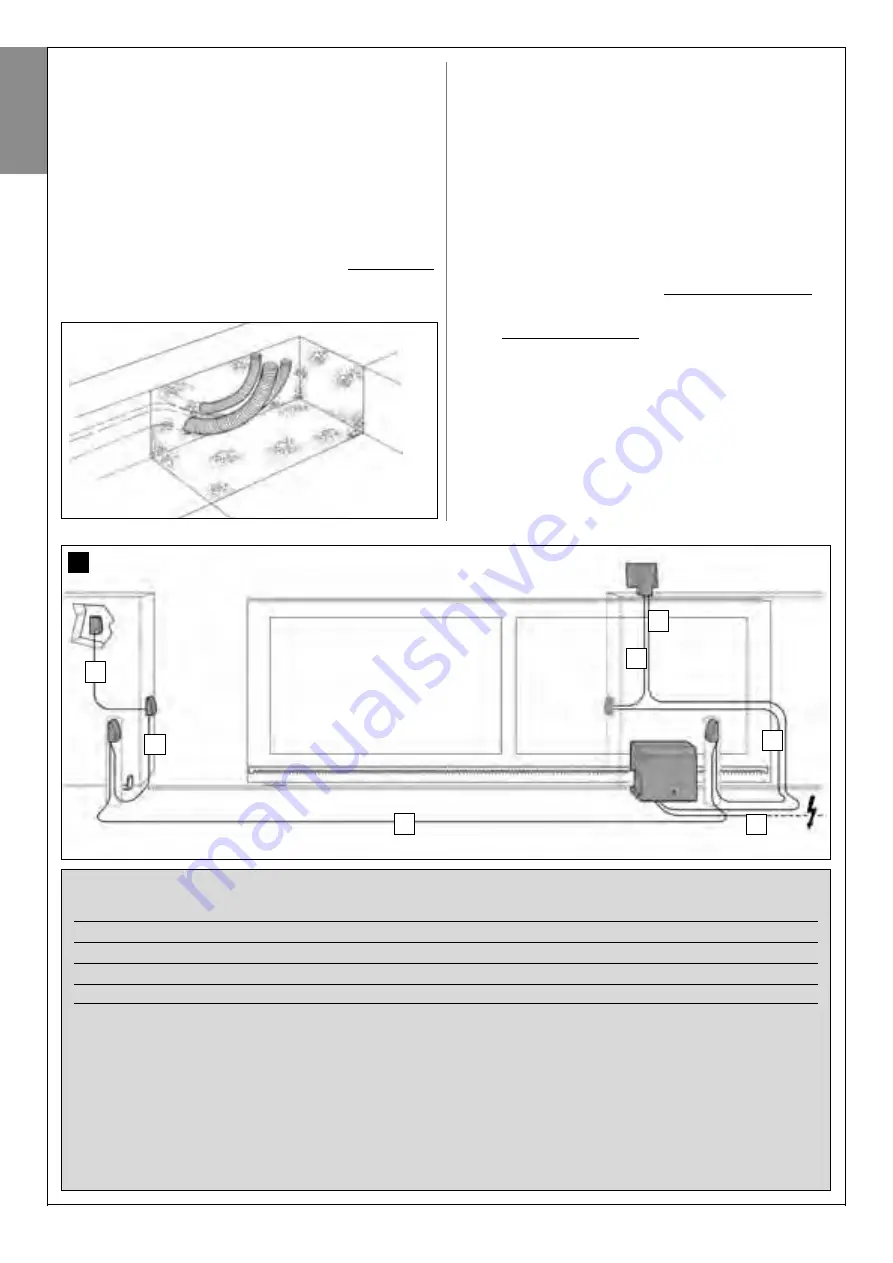

TABLE 1 – Technical specifications of electric cables

(see also paragraph 4.2)

Connection

Cable type

Maximum admissible len

A

- FLASHING LIGHT cable

Cable 2 x 1.0 mm

2

10 m

(note 2)

B

- POWER SUPPLY cable

Cable 3 x 1.5 mm

2

(note 1)

30 m

D

- BUS cable

Cable 2 x 0.5 mm

2

20 m

(note 3)

Note

– The cables required for the set-up of the system (not included in the pack) may vary according to the quantity and type of

components envisaged for the system.

Note 1

– If the power cable supplied is not long enough, replace with a cable of this type. This task must be performed by skilled

and qualified personnel: Refer to the section “

Tasks reserved for qualified technicians

”.

Note 2

– If a greater length is required use a cable with diameter 2 x 1.5 mm

2

.

Note 3

– If a greater length is required use a cable with diameter 2 x 1.0 mm

2

.

CAUTION!

– The cables used must be suited to the installation environment; for example a cable type H07RN-F for out-

door environments is recommended.

4.1

.5 –

Checking the tools required for work

Before starting installation, ensure that there is all equipment and materi-

als required for the work concerned (see example in

fig. 6

); also ensure

that all items are in good condition and comply with local safety stan-

dards.

4.1

.6 –

Preliminary set-up work

Dig the routes for the ducting used for electrical cables, or alternatively

external ducting can be laid, after which the pipelines can be embedded

in concrete and other preparation work for the installation can be com-

pleted to finalise the site ready for subsequent installation operations.

In particular, for digging the pit for anchoring the gearmotor to the

ground, proceed as follows:

01.

Dig the foundation pit in the gearmotor fixture point: refer to STEP

3.2

.

Note

– The dimensions of the pit must be the same or greater than

those of the foundation plate.

02.

Lay the ducting used for electrical cables as shown in the figure

below.

CAUTION!

– In general, position the ends of the ducting used for

electrical cables in the vicinity of the points envisaged for fixture of

the various components.

Note:

The ducting serves to protect electrical cables and prevent acci-

dental damage in the event of impact.

4.2

– PREPARING THE ELECTRICAL CABLES

When preparing the electrical cables required for your system, please

refer to

fig. 7

and “

Table 1 – Technical characteristics of the electric

cables

”. In addition to this, you should always remember the following:

– In the “star” configuration, NONE of the individual cables linking up

any of the devices to the Control Unit may exceed 20 m in length.

– In the “chain” configuration”, the sum of the lengths of each cable

used to connect one device to the other and, last of all, to the Con-

trol Unit MUST NOT exceed 20 m.

– If connecting other devices between the Control Unit and the flash-

ing lamp, use the same cable for these devices as was used for the

flashing lamp.

– All operations to lay the electric cables and connect them to the

various devices must be carried out during installation of the com-

ponents.

7

A

B

C

C

C

C

C