Replacing the Fuser Unit and Transfer Roller Kit

25

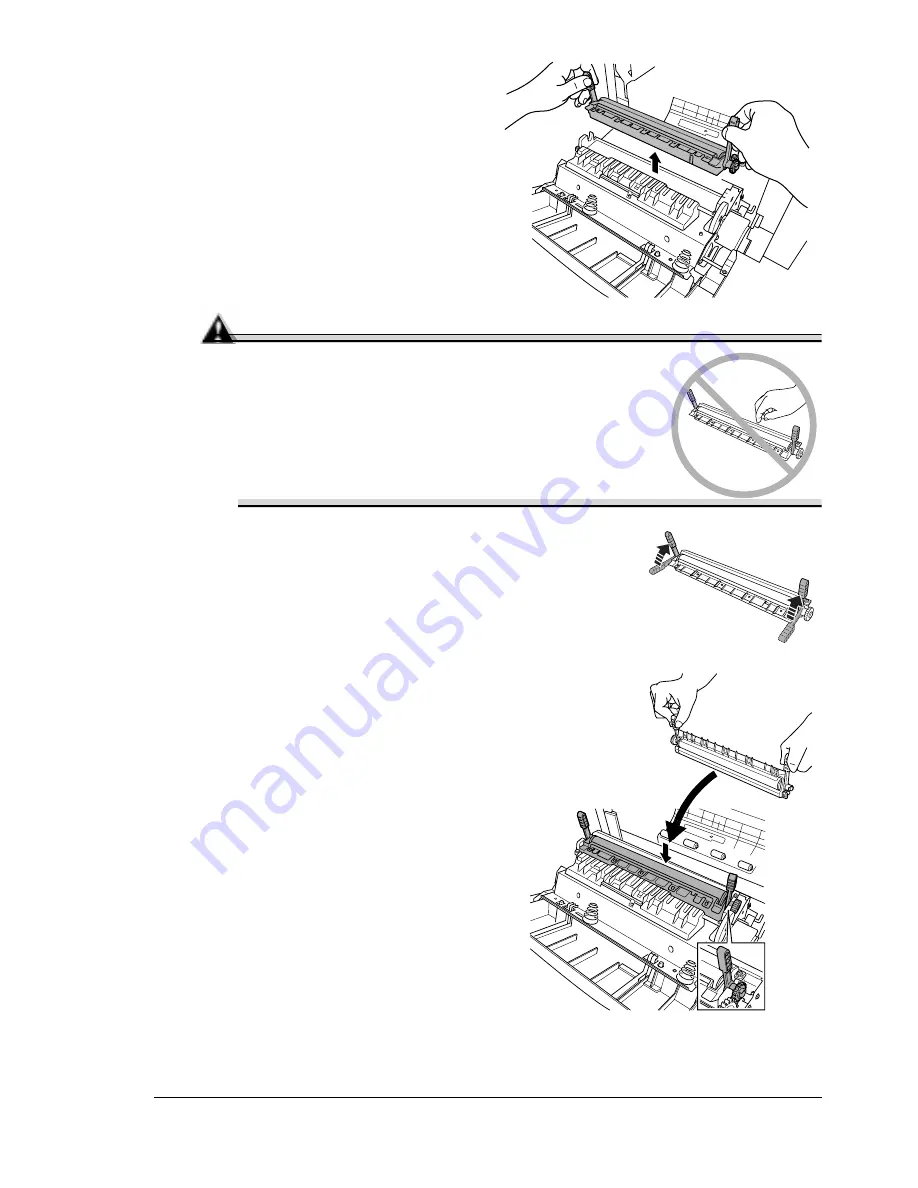

2

Holding the two transfer roller

unit handles, remove the trans-

fer roller unit.

5

"

Dispose of it properly

according to your local

regulations.

3

Remove the new transfer roller

unit from the fuser kit box.

Attention

Do not touch the surface of the transfer roller

unit. This could lower image quality.

4

Place the new transfer roller unit on a

level surface.

5

Lift up the two transfer roller unit handles.

6

Holding the two transfer roller unit

handles, carefully lower it so the

transfer roller unit shaft goes into

the two transfer roller unit installa-

tion guides.

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Summary of Contents for magicolor 2210

Page 1: ...magicolor 2210 User s Guide 1800669 001B EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 7: ...1 Replacing Consumables EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 34: ...EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 35: ...2 Using Media EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 49: ...3 Maintaining the Printer EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 53: ...4 Troubleshooting EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 101: ...5 Installing Other Accessories EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 140: ...EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 141: ...6 Color Printing EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 144: ...EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 145: ...7 Repacking the Printer EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 155: ...A Technical Specifications EDNord Istedgade 37A 9000 Aalborg telefon 96333500...

Page 176: ...EDNord Istedgade 37A 9000 Aalborg telefon 96333500...