19

20

●

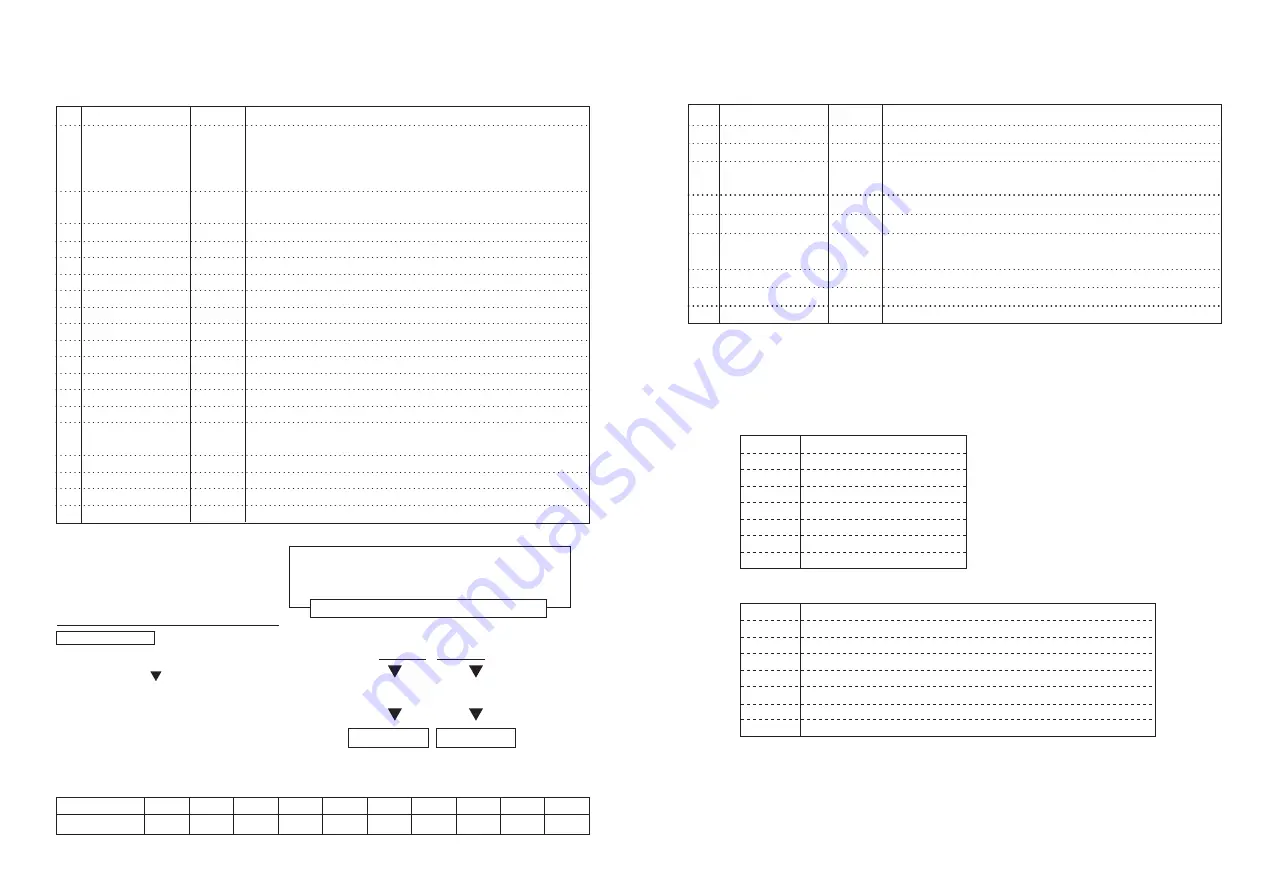

Data Contents (Command 1)

When Control Pack receives a command 1 "$44 $41 $0D", the following data 20 bytes

shall be transmitted.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

$2A

Selector operating

mode

Setting rotation

directions

Setting rpm.

Setting rpm.

Setting rpm.

Rpm

Rpm

Rpm

Motor current value

Motor current value

Motor current value

Motor voltage value

Motor voltage value

Motor voltage value

Error number

Error number

Checksum

Checksum

$0D

10^ 1

10^ 0

10^ ‑1

10^ 1

10^ 0

10^ ‑1

10^ 1

10^ 0

10^ ‑1

10^ 1

10^ 0

10^ ‑1

10^ 1

10^ 0

(H)

(L)

The head of data is shown. It's ASCII code "*".

$31 Panel operation mode

$32 Remote operation mode

$33 Selector operation mode.

$34 Panel/RemoteSelector operating mode.

$30 CW (Forward rotation)

$31 CCW(Reverse rotation)

Two‑digit number of setting rpm. is shown by ASCII code.(unit:kmin ‑1)

One‑digit number of setting rpm. is shown by ASCII code.

1/10‑digit number of setting rpm. is shown by ASCII code.

Two‑digit number of the motor rpm. is shown by ASCII code.(unit:kmin ‑1)

One‑digit number of the motor rpm. is shown by ASCII code.

1/10‑digit number of the motor rpm. is shown by ASCII code.

Two‑digit number of the motor current value is shown by ASCII code.(unit:A)

One‑digit number of the motor current value is shown by ASCII code

1/10‑digit number of the motor current value is shown by ASCII code

Two‑digit number of the motor voltage value is shown by ASCII code(unit:V)

One‑digit number of the motor voltage value is shown by ASCII code

1/10‑digit number of the motor voltage value is shown by ASCII code

Two‑digit number of the error number is shown by ASCII code.

when error has not arisen, it's "00" ($30 $30)

One‑digit number of the error number is shown by ASCII code.

Higher rank checksum data is shown.

Lower rank checksum data is shown.

The last of data is Control Code "CR".

(For checksum calculation method)

From data No.1 to the 17th

「$2A」〜「Error number10^ 0 」

Upper 4 bits Lower 4 bits

「○○○○○・・○○○○ ○○○○ 」

Add "$30" respectively.

←Lower 8 bits

Checksum (H)

Checksum (L)

(Relation between a number and ASCII code)

(Calculation example)

Lower 8 bits of total to the transmitting data

=1011 0101

●Checksum (H)

1011 + $30 = $0B + $30 = $3B

●Checksum (L)

0101 + $30 = $05 + $30 = $35

Number

ASSCII code

0

$30

1

$31

2

$32

3

$33

4

$34

5

$35

6

$36

7

$37

8

$38

9

$39

Transmitting data total

Transmitting data

●

Data Contents (Command 2)

When Control Pack receives a command 2 "$44 $42 $0D", the following data 20 bytes

shall be transmitted.

●

Contents of External Input/Output Signals

The input signal from CONTROL connector is shown in "Chart‑3" and output signal is

shown in "Chart‑4". In the relation between the input signal and the bit value, Bit

is "1" in case of the input signal "ON" and is "0" in case of "OFF".

1

2

3

4〜

6

7

8

9〜

17

18

19

20

$2A

Air pressure

Air pressure

External input signal

External output signal

Checksum

Checksum

$0D

10^ ‑ 1

10^ ‑ 2

(H)

(L)

It is the head of data. It's ASCII code "*".

1/10‑digit number of the air pressure value is shown by ASCII code.(unit:Mpa)

1/100‑digit number of the air pressure value is shown by ASCII code.

Confirming the operation of factory shipment

Refer to Chart‑3 "Contents of External input signal".

Refer to Chart‑4 "Contents of External output signal".

Confirming the operation of factory shipment

Higher rank checksum data of transmitting data is shown.

Lower rank checksum data of transmitting data is shown.

The last of data is Control Code "CR".

External Input Signal

External Output Signal

Bit 7 always 0

Bit 6 always 0

Bit 5 always 1

Bit 4 always 1

Bit 3 always 0

Bit 2 external reset signal

Bit 1 external start signal

Bit 0 external rotation signal

Bit 7 always 0

Bit 6 always 0

Bit 5 always 1

Bit 4 always 1

Bit 3

Motor stop signals "1" during pauses/ "0" be in action

Bit 2

Speed attainment signals "1" attainment / "0" in transit

Bit 1

Motor connection signals "1" normal connection /"0" error

Bit 0

Alarm signals "1" normal operation / "0" error

Chart‑3

Chart‑4

Summary of Contents for SFIDA 01 Series

Page 12: ......