6-2

Specifications

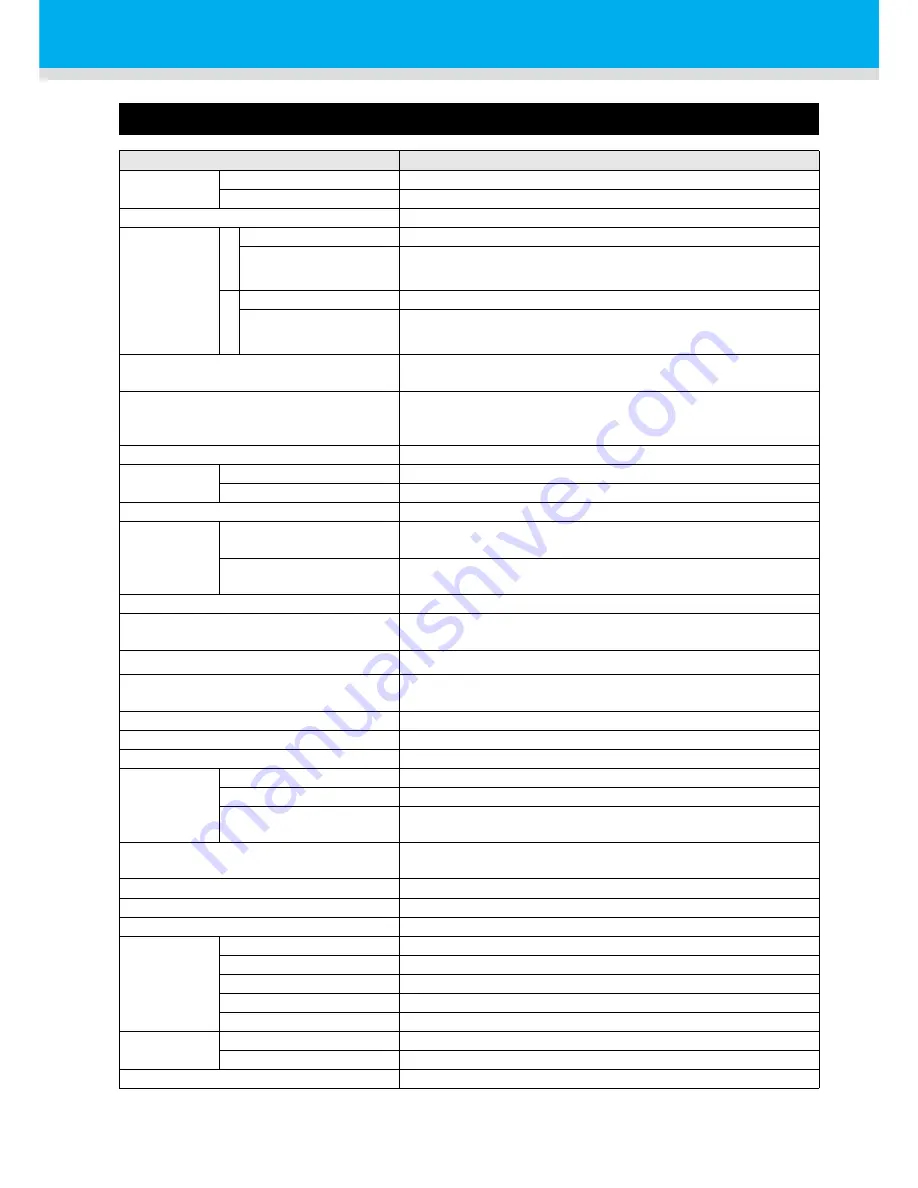

Basic unit specifications

Item

UJF-706

Drawing

head

Method

On demand piezo-head

Specification

6-heads (12 nozzle rows)

Resolution

600 dpi, 1200 dpi

Drawing

mode

4 Color

600 x 600 dpi

2 pass Unidirection / 4 pass / 8pass Unidirection (H.S.)

1200 x 1200 dpi

4 pass Unidirection / 8 pass / 16pass Unidirection (H.S.)

8 Color

600 x 600 dpi

4 pass Unidirection / 8 pass / 16pass Unidirection (H.S.)

1200 x 1200 dpi

8 pass Unidirection / 16 pass / 32pass Unidirection (H.S.)

Usable ink

Genuine UV curing ink

Total 7 color: Bk, C, M, Y, Lv, Lm, 6 color and white, Clear

Ink supply

Supplies ink through a tube from ink cartridge

Remaining ink display function

Ink end detection function

Ink capacity

440cc (1 for each color)

Usable

media

Size

710 x 605 mm or less

Thickness

0.2 to 150mm

Max. drawing range

W 700 x L 600 mm or less

Distance

accuracy

Absolute accuracy

The large of the two; ± 0.3 mm or ±0.3% of a specified dis-

tance.

Reproducibility

The large of the two; ± 0.2 mm or ±0.1% of a specified dis-

tance.

Perpendicularity

± 0.5 mm/500mm

Head gap adjustment

Automatic head gap adjustment enabled. The media surface

is sensed with the area sensor, moving up or down the table.

Media absorption

Absorption fixing by absorption fan

*1

*1. The blower is an option.

UV unit

UV irradiation device embedded

UV power supply

Waste ink tray

Tray type (400cc)

Interface

USB2.0 compliance (The cable is optional)

Command

MRL-III

Noise

Stand-by

Less than 58dB (FAST-A, 1m in all direction)

Operation continuous noise

Less than 65 dB

Operation discontinuity

noise

Less than 70dB

Safety standards

CE Marking (Low Voltage Directive, EMC Directive), CB Report,

UL60950-1, VCCI classA, FCC classA, and RoHS Directive

Ink safety

MSDS

Power specification

Single phase AC 200 to 240V x2

Power consumption

Less than 4.0kVA (Main unit:1kVA, UV device:3kVA)

Environment

Available temperature

15 to 30

℃

Humidity

35 to 65%Rh (No condensation)

Guaranteed temperature

18 to 25

℃

Temperature change

±10

℃

or less

Dust

Equivalent to normal office level

Weight

Main unit

Approx. 500 kg

UV power supply

14kg

Outside dimensions

2500 (W) x 1750 (D) x 1550 (H) mm

Summary of Contents for UJF-706

Page 1: ...D202102 20 MIMAKI ENGINEERING CO LTD URL http eng mimaki co jp is ...

Page 7: ...vii ...

Page 36: ...1 18 ...

Page 58: ...2 22 ...

Page 94: ...3 36 ...

Page 142: ...4 48 ...

Page 156: ...5 14 ...

Page 169: ...6 13 Function Flowchart 6 Appendix ...

Page 182: ...6 26 ...

Page 183: ...D202102 20 01022013 ...