© 2014 MIMAKI ENGINEERING CO.,LTD.

7.6

P.10

7.6 Image Quality Adjustment

R.1.2

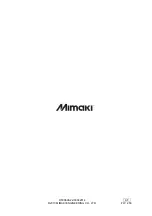

7. Check and compensate the patterns.

Input the adjustment value (the measured value:

μ

m) so that the

impact dots of other nozzle lines (7 lines) are at the same

position in the Y-direction, referring to the reference nozzle

H1A line.

Check and execute the compensation for H1A-H1B ~ H2D.

[

] / [

] : Compensating value input (Input unit: 20 µm)

[ENTER] : Confirms (Next)

8. When compensated, draw and check the patterns again.

Return adjustment

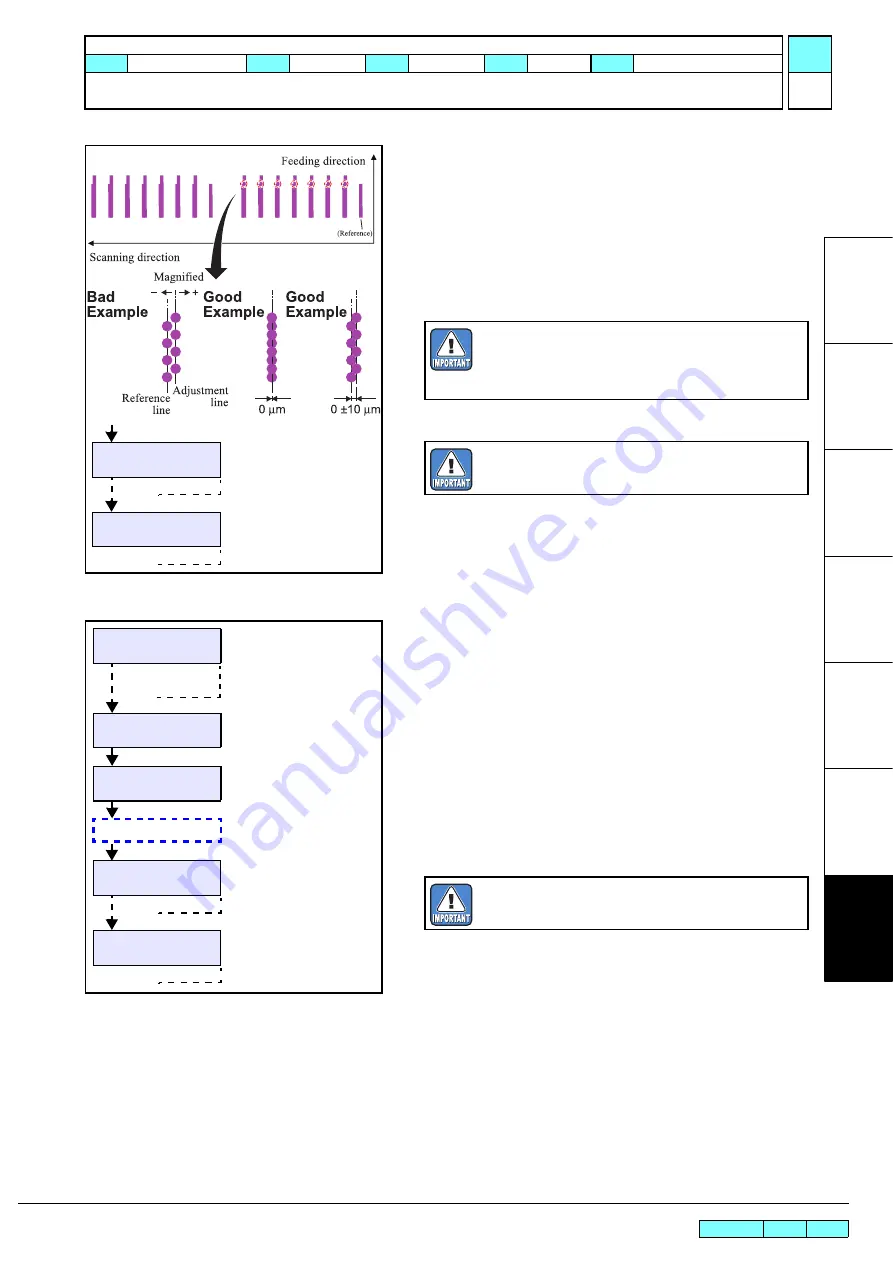

9. On the [SELECT] display, select “ReDir”, and adjust it in the

same way as “SiDir”.

[

] / [

] : Switches

[ENTER] : Confirms (Next)

10. Press the [ENTER] key to draw the pattern.

[ENTER] : To start Pattern drawing

[

] : To the compensation display

(Without drawing)

11. When compensated, draw and check the patterns again.

900Hi SiDir WF1

H1A-H1B : 0.0

-99.9~99.9

900Hi SiDir WF1

H1A-H1C : 0.0

-99.9~99.9

Magnify by a microscope, and

measure it in inside readings.

Input the compensating value, referring to the left

figure, if the displacement on the drop position of

head applied for the compensation occurs either right

or left against the reference head.

Repeat “Drawing -> Checking (Compensating)” until

any compensation is not required.

#PRINT ADJUST

SELECT:ReDir

#PRINT ADJUST

ReDir:PRINT

Pattern drawing

SiDir

BiDir

#PRINT ADJUST

SELECT :ReDir

900Hi ReDir WF1

H1A-H1B : 0.0

-99.9~99.9

900Hi ReDir WF1

H1A-H1C : 0.0

-99.9~99.9

Repeat “Drawing -> Checking (Compensating)” until

any compensation is not required.

INSTALLATION GUIDE > Outputting Plots > Image Quality Adjustment

Model

JV400-130/160LX

Issued 2011.02.15 Revised 2013.10.10 F/W ver.

2.50

Remark

1.2

Summary of Contents for JV400-130LX

Page 49: ......

Page 50: ...D500698 22 30042014 2013 MIMAKI ENGINEERING CO LTD KF FW 2 50...