4. Consumable Item Replacement

31

5

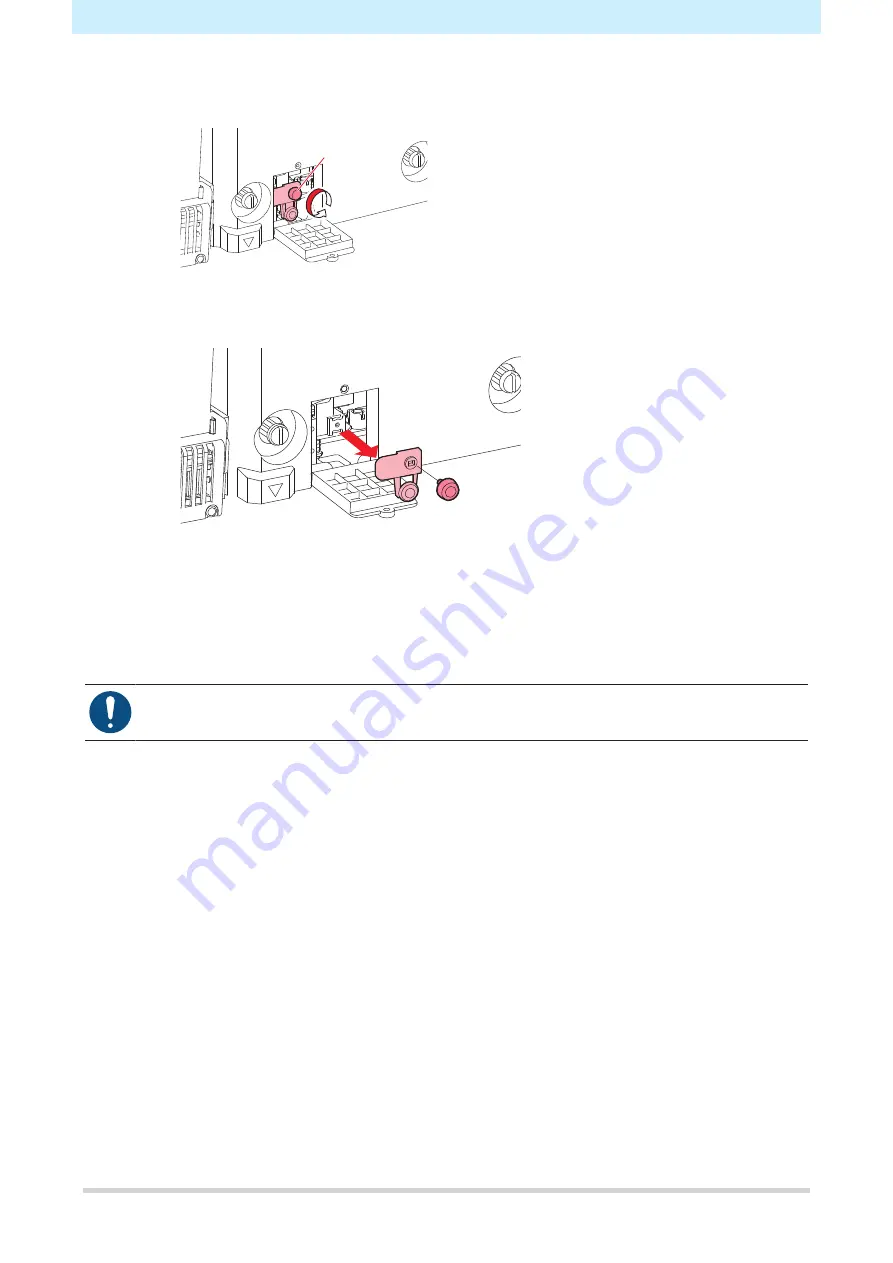

Replace the media cutter.

(1) Unscrew the cutter screw.

Screw

(2) Remove the cutter.

(3) Attach a new cutter.

(4) Tighten the screw to clamp the cutter.

6

Close the carriage cover hatch, then retighten the screw.

7

Once replacement is complete, close the front cover, then press the [ENTER] key.

• When disposing of the product, contact an industrial waste disposal operator or dispose of the

product in accordance with the local laws and regulations.