Mighty Therm HH-PH Hydronic Boilers

Page 13

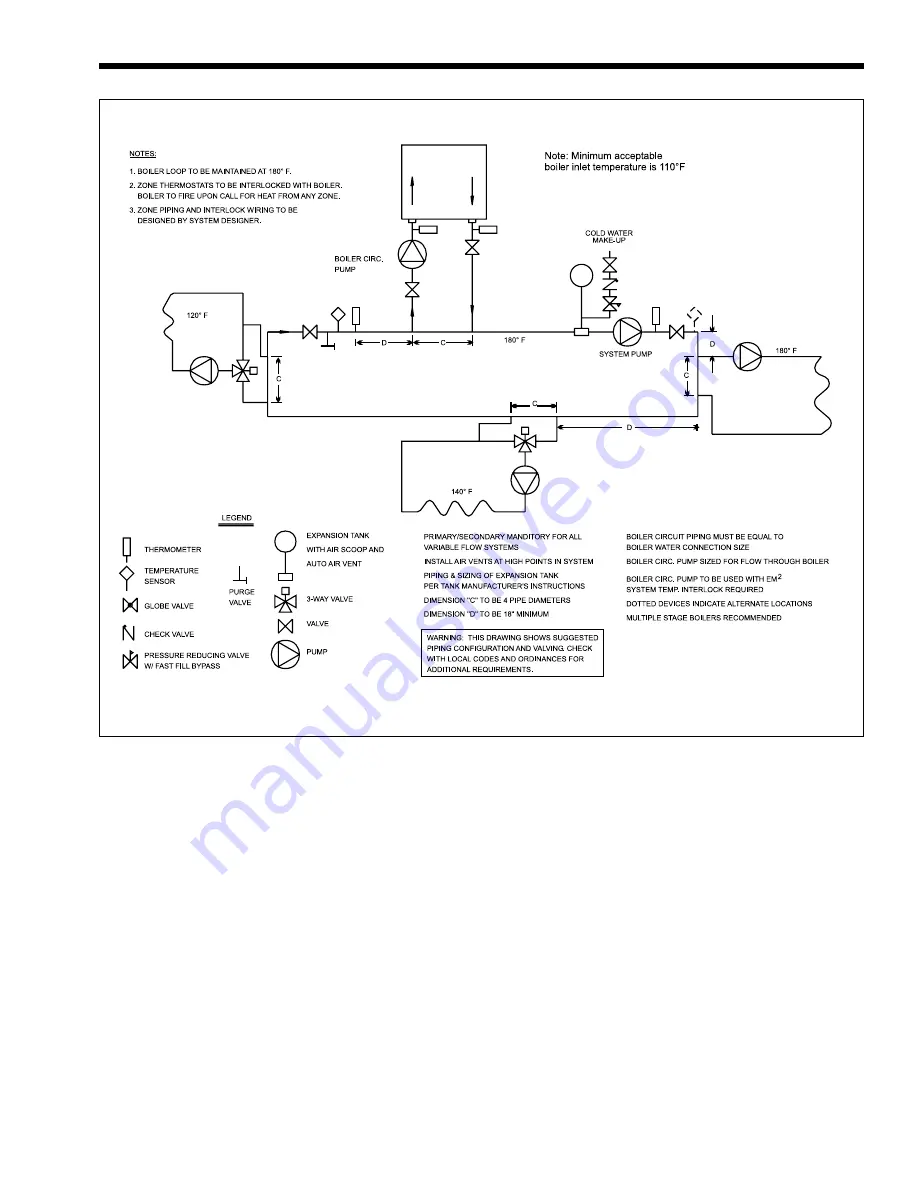

Figure 23. Hydronic Piping — One Boiler, Multi-Temperature System.

The correct flow rate can be verified by checking

the temperature rise of water as it passes through the

boiler. To check the temperature rise, measure the

difference in water temperature between the boiler

inlet and outlet to determine flow. For example: If a

Size 325 boiler is installed; the inlet water temperature

is 160°F (71°C); and the outlet water temperature is

185°F (85°C); then there is a 25°F (14°C) temperature

rise. Per Table 3 this equals a flow rate of 20 GPM

(1.3L/s) and a head loss (pressure drop) of 2.1 feet of

water. If a higher temperature rise is measured, flow

must be increased by changing the piping or pump

size.

2F-4. Variable Water Flow Systems

There can be reduced water flow through the

boiler in heating systems using zone valves, zone

pumps or 3-way valves. This can result in a high

temperature rise across the boiler. Laars recommends

primary-secondary pumping for all variable flow

systems. The boiler pump in a primary-secondary

system maintains constant flow through the boiler

even though the system flow is variable. In a primary-

secondary system the pressure drop of the boiler is not

added to the system (see Figures 21, 22 and 23).

2F-5. System Pressure Requirements

The HH-PH boilers are designed to operate on

closed, pressurized systems. A minimum of 12 psi

(82.7kPa) should be maintained on the system where

boiler supply water temperatures are 200°F (93°C) or

less. If higher temperatures are required, the minimum

system pressure should be at least 15 psi (103.4 kPa)

above the water vapor pressure corresponding to the

elevated water temperature.

Do not use the HH-PH boilers to operate on

open, pressurized systems unless the supply water

temperatures are kept below 180°F (82°C), and a

minimum of 5 psi (34.5 kPa) static head is maintained

at the boiler.