OmegaPATPlus / BetaPATPlus Other instrument operations

76

From the

Main menu

, select

Setup

and then select

Instrument settings

by using

¿

and

À

cursor keys and press ENTER key to confirm. The

Instrument settings

submenu

will be displayed.

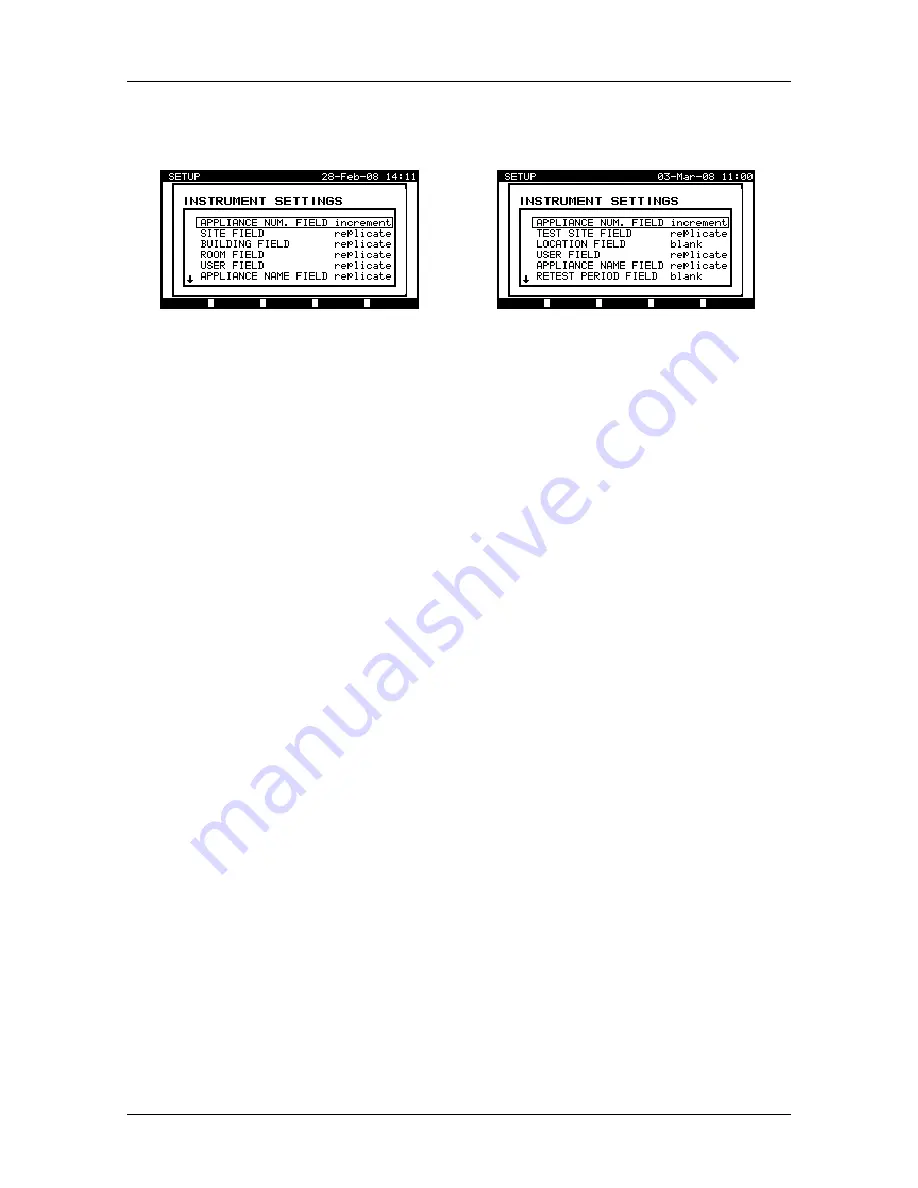

Aus/ NZ model

UK model

Instrument settings menu

The following data can be controlled between tests:

UK model

Aus/ NZ model

Ì

appliance

number,

Ì

test

site,

Ì

location,

Ì

user,

Ì

appliance

name,

Ì

retest

period

Ì

repairing

code,

Ì

comments,

Ì

barcode

system.

Ì

appliance

number,

Ì

site,

Ì

building,

Ì

room,

Ì

user,

Ì

appliance

name,

Ì

retest

period,

Ì

repairing

code,

Ì

comments,

Ì

barcode

system,

Ì

second tag manipulation.

By using

¿

and

À

cursor keys select the item whose parameter you want to change

and press ENTER key to confirm. Use

¿

and

À

cursor keys again to set parameter to

your needs. Press F1 function key to confirm. To restore last used setting for selected

item press F2 key.

In general, the

blank

and

replicate

options are available. If

blank

is selected for a

particular item, then the appropriate field will initially appear blank in the

Save results

menu. If

replicate

option is selected for a particular item, the last entered data will

initially appear in an appropriate field when new autotest sequence is finished.

The

increment

option can also be set in the

appliance number

field. In this case, the

appliance number will be automatically incremented when new autotest sequence is

finished.

Notes on Aus/NZ model:

Ì

The

2

nd

appliance number and its name can also be added to the actual autotest

results. To activate this functionality

enable

the

2

nd

tag manipulation

. When

2

nd

tag manipulation

is

disabled

, then only one appliance number and its name is

available in

Save results menu

when new autotest sequence is finished.

Ì

When

2

nd

tag manipulation

is

enabled

, two appliance barcode labels are

printed out.