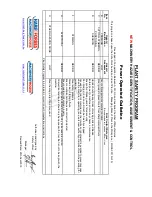

Power Operated Guillotine Safety Instructions

1. Maintenance.

Make sure the Guillotine is turned

off and disconnect from the main power supply

and make sure all moving parts have come to a

complete stop before any inspection, adjustment or

maintenance is carried out.

2. Guillotine Condition.

Guillotine must be

maintained for a proper working condition. Never

operate a Guillotine that has low oil levels, damaged

or worn parts. Scheduled routine maintenance

should performed on a scheduled basis.

3. Blade Condition.

Never operate a Guillotine with a

damaged or badly worn blades. Replace if required.

4. Pump Direction.

Pump rotation must be in arrow

direction otherwise the pump will be damaged.

5. Hand Hazard.

Keep hands and fingers clear from

moving parts. Serious injury can occur if hand or

finger tips come between blades.

6. Personal Protection.

Gloves are recommended

when handling the workpieces.

7. Authorized and trained personnel.

The machine

must be operated by authorized and trained

personnel. The shear is designed to be operated

be a single user. Using the machine with more

than one operator is forbidden, except for certain

maintenance situations.

8. Power outage.

In the event of a power failure

during use of the machine, turn off all switches

to avoid possible sudden start up once power is

restored.

9. Work area hazards.

Keep the area around the

Guillotine clean from oil, tools, objects & chips. Pay

attention to other persons in the area and know what

is going on around the area to ensure unintended

accidents.

10. Guards.

Operate machine only with all protective

devices and guarding in place and operational.

Never remove, defeat or bypass. Any presence-

sensing safeguarding used must have regular

Safety integrity tests and records kept. These

records must be kept for 5 years or for the life of

the plant and be handed to any person that you

relinquish control of the plant to. Tests include stop

time measurements , safety distance calculations

and inspections, with operator checks and periodic

maintenance checks. (WHS Regulation 226)

11. Material.

Material must NOT be hardened ceramic

or glass-originated, non flat metals (at origin) e.g.

rods, bars, tubes & pipes.

12. Blade gap adjustment.

Do NOT operate the

machine without proper blade gap adjustment

according to sheet thickness.

13. Warning Labels.

Take note of any warning labels

on the machine and do not remove them.

14. Backgauge Area.

Do not access the backgauge

area, while the machine is working.

15. Protective fence.

Do not bridge the safety limit

switch of the rear protective fence.

16. Squaring arm.

Do not use side squaring arm

and front support arms for intermediate storage of

workpieces.

17. Operation.

During the shearing process, the

workpiece may slide or move unexpectedly.

Therefore, the material must be handled carefully.

18. Emergency stop.

Use the emergency stop button

in case of any emergency.

19. Level machine.

Level the machine on a flat

concrete surface by using a spirit level.

20. Overloading machine.

Do not exceed the rated

capacity of the guillotine. Please refer to the

manual for capacities.

21. Hearing protection and hazards.

Always

wear hearing protection as noise generated from

machine and workpiece can cause permanent

hearing loss over time.

22. Call for help.

If at any time you experience

difficulties, stop the machine and call you nearest

branch service department for help.

Machinery House

requires you to read this entire Manual before using this machine.

Page 35

Instructions Manual for HG-4012 (S948)

12/02/2018