20

OPERATION MANUAL

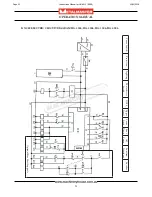

NC89 Swing Beam Guillotine Controller operation

X. Pos:

Back gauge position.

Operation:

Move Arrow to X Pos, clear number

, enter desired value, press and start button.

The back gauge will now go to the new entered position to within 0.5mm. Once back gauge has stopped searching use

the manual handle for fine adjustment.

Count:

Number of cuts.

Count can be cleared at any time by using clear button, It will then count upwards with each cut. A set number

can also be entered.

Operation:

Move Arrow to Count, clear the number, enter eg. 3 and press After

3 cuts it will count down to 0 and the controller will stop cutting. You must now arrow down to Count and then

press for counting upwards or enter any number for counting downwards.

Timer:

Length of cut.

The length of cut can be changed to suit the width of material being cut.

Operation:

Arrow down to timer, clear value

and enter new value for cut length time, press and start button.

Mode:

Cont / Single

Mode Single -

Used to perform 1 cut at a time when foot pedal is pressed.

Mode Cont -

Used to perform continuous cutting when foot pedal is pressed.

Arrow

Clear

Stop

Start

Mode

5.2 NC89 CONTOLLER OPERATION

Page 20

Instructions Manual for HG-4012 (S948)

12/02/2018