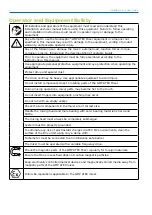

NOTE

Consult the parameter settings and

circuit and terminal diagrams before

installing the control cabinet.

Validate the current media and

process conditions. If the production

conditions are in any way altered after

commissioning of the mixer, a new

validation must be performed.

Validate the possible minimum and

maximum operating speed for each

process.

Catalog

Number

Design Speed (rpm)

NOTE: Design Speed is the

Mechanical Limit

AX05/41

50 – 400

AX1/41

50 – 400

AX5/41

50 – 400

AX10/41

50 – 400

AX20/41

50 – 400

AX50/41

50 – 400

AX100/41

50 – 400

AX200/41

35 – 280

!

Set VFD unit to 100% nominal

power (kW) and current (A) of the

motor rating.

Excess force may cause magnetic

decoupling.

Electric motors (and VFD system

parts, i.e. sensors) when working

with driven equipment are capable

of causing an explosion in an

explosive atmosphere. Consider

this when selecting parts for the

system in ATEX environment.

Operation

!

Ensure that the installation has

been performed correctly and

that the parameters are correctly

programmed.

Ensure that no one is working

inside the vessel.

Ensure that a sufficient level of

liquid covers the mixing head

and the male bearing to ensure

sufficient lubrication of the

bearing.

The mixing head must be covered with

liquid during operation with explosive

media.

Never work close to the drive unit

while it is connected to its driving

source. Keep away from moving

parts.

Regulate speed, acceleration, and

deacceleration carefully to avoid

magnetic decoupling.

Stop the mixer immediately if any

signs of malfunction, abnormal

noise, or smell occurs.

Do not exceed operation

temperature of 135 ºC (275 ºF)

inside vessel.

Use extra precaution because of

pressure buildup when the mixer is

running at high speed and:

•

with hot WFI

•

at atmospheric pressure

•

during or after steam

sterilization

Starting the Mixer

1. Fill the vessel to a minimum level that

completely covers the mixing head and

the male bearing to provide sufficient

lubrication of the bearing.

2. Start the mixer and slowly increase to

a minimum speed (50 rpm). (Note: the

first time the mixer is started, run it for a

few seconds at this speed and check that

the motor fan is turning in the correct

direction.)

3. Increase the speed slowly to working

speed. If the mixer makes a rumbling

noise, stop the mixer immediately and

consult the troubleshooting section in this

user guide.

NovAseptic

®

GMP ATEX Mixer

15

Summary of Contents for EMD Millipore NovAseptic

Page 2: ...2 Installation and User Guide ...

Page 4: ...4 Installation and User Guide ...

Page 31: ...NovAseptic GMP ATEX Mixer 31 ...