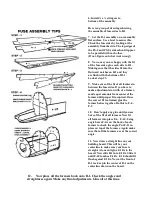

B1 Assembly

1.

Join the FS-2 and FS-2a using a straight edge along the top of

these parts.

2.

When ready to make up the other side, assemble it right on top of

the first side thus assuring that both sides are exactly the same.

Use wax paper between the sides so they do not glue together.

3.

Check to make sure both sides are exactly the same.

4.

Glue the FS-3 to the bottom of FS-2 – FS-2a assembly. Use a

straight edge at the bottom of FS-2a when sliding the FS-3 into

position. Check wing saddle to be sure it matches. Again, lay the

next side onto completed one and install FS-3.

5.

Install the 3/4” triangle to B-1. Use a square to block B-1 to insure

the tri-piece is flush to B-1. Draw a centerline down B-1. Now lay

the tri-piece on B-1. It should be flush, almost back to the outward

notches. Now the tri-piece should meet on the centerline at the

rear. After both pieces of tri-stock are in place, you can sand or

cut off excess tri-stock making sure it is flush with B-1. Make sure

you don’t cut or sand off the outward notches.

6.

Now take angle brace F-6A and at each former location, make a

mark up the sides of the tri-stock. (The marks should slant

towards rear B-1) Now with a knife, make a cut 1/8” wide by 1/8”

deep at each of the marked locations. Now you should have a slot

that each of the formers should fit in. Also at the correct angle.

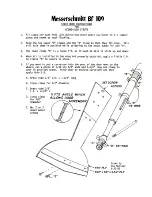

Nose Assembly

Note: It is important that you keep F-2C very straight during assembly.

So check F-2C throughout assembly.

1.

Install the F-2 firewall to the F-2C at 90 degrees. You should

have your centerlines drawn on the firewall.

2.

Slide the F-2 is 90 degrees to F-2C. F-23 should also be flush

with the back of F-2C. Make sure you sand it flush and at 90

degrees before you install F-3.

3.

Install F-1’s and F-3 next. Everything should be 90 degrees

w/F-2C

4.

Install F-1A’s

5.

Install F-T