P070/P071/P085/P086/P100/P101

9-2

9

Faults, causes and remedies

9

Faults, causes and remedies

N O T E

*

) Faults may be eliminated only by authorised personnel

Remedy

See the operating instructions for the

engine

Set drive switch to neutral

position

Press in and lock connection

Replace V-belt

Check V-belt tension, tighten if

necessary

Remove and clean entire pressure-

relief valve, readjust

*

Remove the lock lever (4-8/6)

Open, clean and readjust pressure-

relief valve in control line

*

Storage pressure can be used to bring

the bucket arm to its lowermost position

immediately after an engine failure.

» Does not apply when pipe break

protection is installed «

Remove and clean entire pressure-

relief valve, readjust

*

Replace priority valve

*

Replace filter cartridge

(chapter 8.2.12)

Top up oil

Establish or clean connections

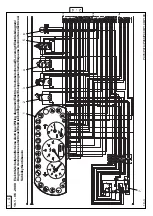

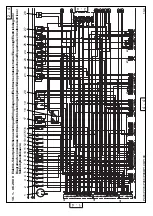

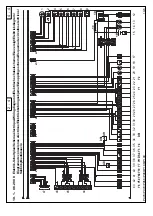

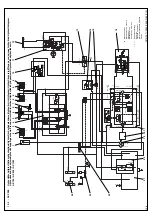

according to electric wiring diagram

Clean

Check setting, adjust if necessary

*

Check whether electrical traction

drive interruption is connected to

brake lever

Probable cause

Drive switch (4-10/11) is not in neu-

tral position

Loose connection

V-belt torn

Alternator speed too low

Pressure-relief valve in servo valve is

open

Pilot valve for working hydraulics

(4-8/4) is locked

Pilot pressure too low or does not

exist

Diesel engine failed

Pressure-relief valve in steering unit

is open

Slide in priority valve stuck

Clogged filter

Lack of oil in hydraulic oil reservoir

Electrical connection at axial piston

pump are not tight, are not connected

or are oxidised

High-pressure valves soiled

Parking brake does not hold the device

Fault

Engine

Engine does not start.

Alternator does not charge

The bucket arm cannot be lifted/

lowered

Steering is sluggish

Faults in the driving and working

hydraulics

Faults in the braking system

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...