P070/P071/P085/P086/P100/P101

6-4

6

Attachments

2

1

1

2

Figure 6-7

Figure 6-8

Figure 6-9

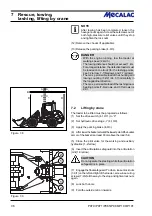

(3) Pick up the bucket using the quick-change device and,

by simultaneously tilting the quick-change device, raise the

bucket until the quick-change device is next to it (6-7).

(4) Lock the bucket with the pilot valve for the auxiliary

hydraulics (4-8/5).

(5) Check that the device is mounted and locked correctly

on both sides.

DANGER

The two bolts of the quick-change device must be

in the bore holes of the bucket suspension and

must be clearly visible (6-8/arrow).

(6) Shut down the engine.

(7) Depressurise the hydraulic lines. For this purpose,

move the pilot valve for the auxiliary hydraulics (4-8/5) back

and forth several times.

(8) Pull off the protective caps from the hoses of the quick-

change device (6-9/1).

(9) Swing up the protective flaps of the quick-change

couplings on the multi-purpose bucket (6-9/2) and connect

them with the hoses of the quick-change device (6-9) by

tightly pushing them in.

CAUTION

When making connections, make sure that the

hydraulic ports are clean and completely con-

nected.

Dismounting

(1) Place the multi-purpose bucket firmly on the ground.

(2) Shut down the engine.

(3) Depressurise the hydraulic lines. For this purpose,

move the pilot valve for the auxiliary hydraulics (4-8/5) back

and forth several times.

(4) Disconnect the quick-change couplings on the multi-

purpose bucket from the hoses of the quick-change device

by pulling firmly.

(5) Fit the protective caps on the hoses of the quick-

change device (6-9/1).

(6) Start the engine and unlock the bucket:

Press the release button for the quick-change device

(4-8/11) and unlock the bucket with the pilot valves for the

auxiliary hydraulics (4-8/5).

(7) Further dismounting is in the reverse order.

CAUTION

The hydraulic quick-change device must only be

locked

when an attachment has been mounted.

NOTE

The type plate is on the rear of the bucket, on the

right-hand side beneath the cross arm.

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...