P070/P071/P085/P086/P100/P101

1-8

1

Safety regulations

1.5.2.9

Individual pieces and large assemblies must be

carefully secured to hoisting equipment when being re-

placed to avoid any damage. Only suitable and technically

sound hoisting equipment may be used as well as crane

equipment with adequate payload. Do not stand or work

underneath suspended loads!

1.5.2.10

Only experienced personnel should be entrusted

with the securing of loads!

Loads must be secured so that they cannot slip or fall

down.

1.5.2.11

Attached loads may only be moved with the

machine when the road is graded.

1.5.2.12

When working with hoisting equipment / eleva-

tors the slingers may only work with the approval of the

driver and from the side of the boom. The driver may only

give his consent if the machine is standing still and the

working attachment is not being moved.

1.5.2.13

Persons assisting with the guidance of loads and

slingers may only stay in visual or communication reach of

the driver.

1.5.2.14

The operator must move the load as close to the

ground as possible and avoid swivelling the load.

1.5.2.15

The operator may not move the load over the

heads of persons.

1.5.2.16

In the case of erection work that must be carried

out above normal human height, suitable safety ascent

devices and working platforms must be used. Do not use

engine parts, in particular attachments such as buckets,

as climbing and descending facilities. Use safety harnesses

when working at very great heights.

All handles, steps, railings, platforms, scaffolds, and

ladders must be kept free from dirt and ice.

1.5.2.17

Clean the machine, especially connections and

screw connections, before commencement of mainte-

nance work and make sure that the machine is free from oil,

fuel oil or dirt. Do not use aggressive detergents. Use

lintless cleaning rags!

1.5.2.18

Before cleaning the machine with water or steam

jet (high pressure cleaning unit) or with detergent, protect

all areas where water/steam/detergent may penetrate and

affect the functions or safety of the machine by a suitable

cover or by applying tape. In particular, such parts as

engine components, e.g. alternator, generator governor,

starter, air filter, cables and hoses are very delicate.

1.5.2.19

After cleaning completely remove all protection

covering and tape.

1.5.2.20

After cleaning check all pipelines for fuel, engine

oil and hydraulic oil for leakages, loose connections,

abrased parts and damages. Eliminate defects imme-

diately!

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

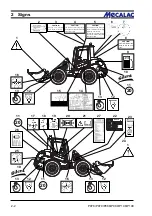

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

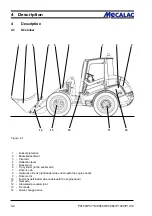

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...