ELECTRICAL

ELECTRICAL CONTROL CENTER

The adjustable safety controls are separated from the

starting controls by means of a partition dividing the

control cabinet and individual access doors. The con-

trol box is further arranged with a dead-front panel

which covers all

e x p o s e d

electrical contacts and

terminals, to provide absolute safety for the operator.

Figure 6, Page 10, shows dead-front panel removed to

show internal controls and wiring.

FIELD WIRING

A.

B.

C.

D.

E.

F.

G.

Wiring should be done in accordance with all ap-

plicable codes and ordinances.

Three main power leads must be hooked up to the

unit power terminal block. Table 8, Page 16, gives

the recommended lead wire sizes for three conduc-

tors in a raceway for a normal installation.

Maximum voltage variation equals 10% of nameplate

value. Phase voltage unbalance must not exceed 2%.

A flow switch (FC) is provided with the unit and

must be field wired across terminals as shown on

Diagrams 2 and 3, Pages 12 thru 15.

Refer to wiring diagrams provided with units for

specific wiring recommendations for each model.

Wiring Diagrams 2 and 3, Pages 12 thru 15, show

basic wiring and accessory circuits.

Always ground unit for safety.

FUSES AND CIRCUIT BREAKERS

The fuses and circuit breakers for the compressor,

condenser fan motor circuit and control circuit are

located in the control box. In addition, there are small

fuses for the compressor control circuit located in the

end of the compressor terminal box. Most local elec-

trical codes also require a disconnect switch in the

power supply, located within reach of the unit. In

many areas, the circuit breaker can be used in place

of a disconnect switch.

Check

on local ordinances

covering specific rcquircments.

CRANKCASE HEATERS

The compressors are equipped with crankcase heaters.

Some models have heaters installed externally below

the crankcase and others have heaters inserted into

the crankcase.

When the system is to be started up initially, the

crankcase heater power should be turned on before

starting the system for a time sufficient for all rcfrig-

erant in the crankcase to be evaporated. This should

be a minimum of 4 hours, and preferably over night.

The crankcase should be up to approximately 80 F.

before the system is started, to minimize the possibil-

ity of lubrication problems or valve damage on start up.

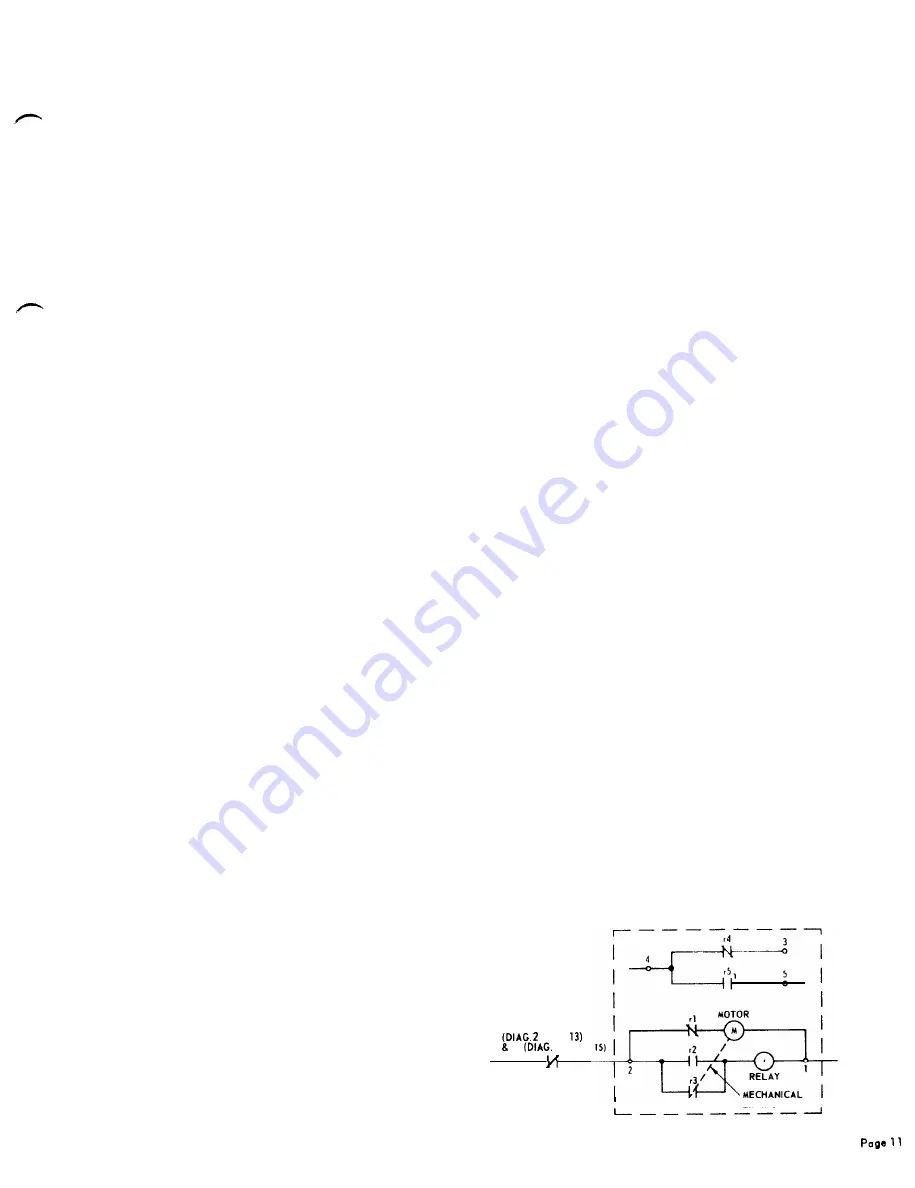

LOCKOUT-TIMER OPERATION

( O p t i o n a l )

(Refer to Diagram 1)

A.

B.

C.

D.

E.

F.

G.

The desired time delay period is set by loosening

the nut at the actuator arm and adjusting the arm

in relation to the calibrated dial. The nut is

tightened.

The sustained contact switch is closed. (Normally

closed R2 in Diagram 2, Page 13).

The clutch motor is energized through the closed

r1 contact. (The relay remains unenergized).

The motor drives the actuator arm and winds up

the reset spring during the timed delay period.

At the end of the delay period, the actuator arm

closes the r3 contact, energizing the r relay.

1. The r2 contact closes and holds the r relay in.

2. The r5 contact closes, energizing the load.

3. The r1 contact opens, de-energizing the motor.

The motor and actuator are reset by the reset

spring. The r3 contact opens up again since it

is actuated only by the actuator arm and is in-

dependent of the relay coil.

When the sustained contact switch is opened, the

r relay coil becomes deenergized. The r5 contact

opens up, de-energizing the load.

The timer is now ready for the next closing of the

sustained contact switch and timed delay period.

DIAGRAM 1 LOCKOUT-TIMER

(INTERNAL WIRING)

R 2

P A G E

R3 R4

3 PAGE

L I N K A G E