CHECKING CONTROLS

As the water warms up, the low stage should

cut in at approximately 49F, which is the inlet and

outlet temperature with the unit off and the high

stage should operate at 54F return.

On a four stage thermostat, the dial setting in-

dicates the cut out point of the low stage switch

which represents the average leaving water tem-

perature desired. The high stage or #4 switch

should be actuated at approximately 51F return

water temperature, #3 at 49F, #2 at 47F, and #1

at 45F, which is the dial setting. The cut in point

will be approximately 2F higher than the cut out

on each switch.

The four stage thermostat has a fixed switch

differential and fixed differential between switches.

Do NOT make any adjustments other than the dial

as this is a preset precision control.

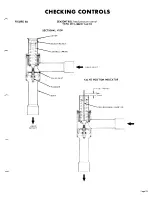

TO CHANGE THE SET POINT:

1.

2.

3.

Loosen the setscrews on the collar below the

hex nut (see Fig. 7).

Turn the hex nut with a wrench to the point

where the desired set point is aligned with the

indicator mark.

Note

:

The set point of this controller is the

break point of switch No. 1.

Lock the setting by tightening the setscrews

loosened in step 1.

CAUTION: Response time on thermostat is slow,

approximately 5 minutes must be allowed (or bulb

response ( a f t e r a t t a i n i n g s y s t e m steady-state

operation) before any or each adjustment to ther-

mostat is made; consequently, it is practicalIy

impossible to accurately calibrate in the field).

FIGURE 7

THERMOSTATS

TWO STAGE

F O U R S T A G E

THERMOSTAT

BULB

SET POINT DIAL

SET POINT

HEX NUT

DIAL LOCKING

SETSCREW

LOCKING SETSCREW (CALIBRATION ONLY)

21