Page 20 / IM 685

Adjustment Procedure for Parallel Valves

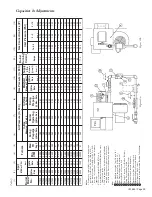

When a manifold pressure adjustment is required, the first step is to adjust the pressure regulator of

each combination gas control to the minimum rate manifold pressure (Table 5, Column 10) while only

that valve is operational, and it is handling approximately its normal maximum rate CFH of gas. The

manual shutoff valve knobs are used to control gas flow so just one valve is operating at a time.

To determine a firing rate suitable for this adjustment, first modulate the burner down to the minimum

rate. At this flow rate only the valve with the highest pressure regulator set point will be operational, the

other valves will be shut down by their integral pressure regulators because the manifold pressure is

slightly higher than their set point. While the burner is operating at that minimum firing rate slowly

close all but one of the manual shutoff valve knobs on the combination gas controls. With care this can

be done without the burner losing flame and shutting down. Watch the manifold pressure manometer

as each valve is being closed. If the manifold pressure starts to drop rapidly in response to the knob

movement, it indicates this combination gas control has the higher pressure adjustment and is supplying

the gas to the manifold. Leave this valve open, and continue closing the remaining valves until only that

one valve is open, and then adjust that combination gas control first.

While the burner is operating and only one combination gas control is open, increase the firing rate of

the burner. As the firing rate is increased the manifold pressure will be relatively constant until the gas

flow rate exceeds the capacity of that single valve and the manifold pressure starts to drop off. The

pressure adjustments should be made at the maximum gas flow rate just before the manifold pressure

starts to drop off, and the following should be considered:

a.

The manifold pressure does not always immediately respond to regulator adjustments. Wait a few

seconds after making an adjuster movement for the regulator to respond and equalize.

b.

When making an adjustment rotate the adjuster CCW until the manifold pressure is below the

desired set point, and then slowly rotate the adjuster CW and nudge the pressure up to the

desired set point.

c.

If the regulator cannot be adjusted up to the required set point, or if that set point seems to be

the highest pressure the reglator can be adjusted to, the flow rate used for this procedure is too

high and must be reduced by repositioning the actuator to a lower firing rate, or the gas supply

line pressure is too low.

After adjusting valve 1, open valve 2. If opening the additional valve does not cause the manifold

pressure to go up, increase the pressure regulator setting of valve 2 until an increase is observed, this

would indicate that the valve has started functioning. Then slowly close the first valve. Proceed to adjust

valve 2. Repeat this procedure until all valves have been adjusted.

Open the manual shut off knobs on all the combination gas controls and modulate the burner up to the

maximum firing rate. The resulting manifold pressure should be close to the Maximum Rate Manifold

Pressure indicated in Table 5, Column 6. If further adjustment is required it should not be necessary to

go through the entire procedure again. If the manifold pressure is to be increased, make small but equal

(about

1

⁄

4

revolution) CW rotations of the pressure adjusting screw on every combination gas control

and check the resulting manifold pressure, both at maximum and minimum rate.

Check Manifold Pressure at Minimum Rate

When several combination gas controls are in parallel and are handling a low flow rate, the combination

gas control with the highest setpoint is essentially handling all the gas. Observe the gas manifold

pressure at the minimum rate. If it is higher than the pressure specified under Column 10 in Table 5,

locate and adjust the dominant combination gas control. Test each combination gas control by slowly

manipulating the manual shutoff knob toward the closed position while observing the manifold

pressure. The pressure will only respond to movement of the knob on the dominant valve. The

manifold pressure will drop as the gas flow is throttled back, using the knob on the combination gas

control to partially close that manual valve.

Generally a valve will be found that has an effect, and very little adjustment will cause a reduction in the

minimum rate manifold pressure. Reduce the pressure adjustment of that dominant valve by slowly

rotating the adjuster CCW until the manifold pressure no longer drops in response to that adjuster

movement.If the manifold pressure is still high after that first adjustment, another valve may have

become the dominant valve and that may also have to be isolated and adjusted to get down to the

specified minimum rate manifold pressure. After making this type of adjustment it is necessary to

recheck the maximum firing rate manifold pressure and perhaps readjust it, making very small but equal

adjuster movements on each valve.