Page 10 / IM 685

Set Control System to Enable Heating

To allow start-up and check-out of the burner, the control system must be set to call for heating and

must be used to control the amount of heating. Set the control system to call for heat so OBA3

energizes Relay R20. With OBA3 closed, vary the temperature control set point to increase, maintain,

or reduce the firing rate of the burner as required for these tests. If OBA4 is closed the firing rate will

decrease. If OBA5 is closed the firing rate will increase. If neither are "made" the firing rate will remain

unchanged.

Start-up Preliminary

1. Before energizing the burner verify that the modulating air and gas valve mechanism moves freely

and is not binding, and check the linkage fasteners for tightness. This can be accomplished without

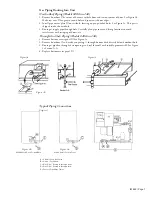

affecting any adjustments. Remove shoulder screw (12), Figure 16a, that connects the teflon bushing

to the actuator crank arm. The control rod can now be manually moved back and forth, it should

feel smooth with no binding or scraping. Always remove shoulder screw (12) and test for binding

after reinstalling the gun assembly on Models HT050-200.

2. Close the gas line cocks. Install a Keyboard Display Module, Honeywell Part No. S7800A1001, or

connect a 20K ohm/volt meter to the test jack on the flame safeguard (see Figure 7).

3. Check the burner fan wheel for binding, rubbing, or loose set screws.

4. Check power. Position switch S3 on burner control panel to AUTO. The LED marked POWER on

the flame safeguard should come on and after a 10 second "Initiate" period the burner motor should

start. Check for CCW rotation as viewed through the burner fan housing inlet. If the motor does not

start, press the reset button on the flame safeguard. If the motor still does not start, consult the

appropriate section of the "Troubleshooting Guide". Continue on to Item 5 when burner motor will

run 10 seconds after the switch is positioned to AUTO.

5. Check voltage. With burner switch S3 at AUTO, measure voltage across burner control box

terminals 2 and NB. If it is not between 114 and 126 volts, check the voltage and tapping

connections to the supplying transformer at the unit main control panel.

6. Purge the gas lines. Turn off electrical power. Remove the

1

⁄

8

inch pipe plug from the inlet pressure

tap of the first electric gas valve in the line. Open the gas line cocks upstream from there and bleed

the gas line of all air. Replace the

1

⁄

8

inch pipe plug.

7. Leak check. Using a rich soap-water mixture and a brush, check the gas lines for leaks. Correct all

leaks before starting burner. After the burner is operating and all the downstream valves are open,

leak check that portion of the gas train.

8. Connect a manometer to measure gas manifold pressure at (1), Figure 16a. There is a

1

⁄

8

inch pipe

size plugged tapping in the gas line just before it enters the burner housing.

Preliminary "Dry" Run

1. Close the gas line cock. Remove the burner front cover and open the control panel door. Switches

LS1 and LS2 in the lower right hand corner of the control box should be in view and the modulating

actuator VM1 should be at the minimum rate position. Verify that the right hand switch LS1 is

being held in the 'made' position by the collar on the control rod and that the switch lever is not

bottomed out against the plastic switch housing.

2. Position the burner switch S3 to AUTO. The flame safeguard will go through a 10 second "Initiate"

period, after which the burner motor will start. The modulating gas valve actuator VM1 will drive

the air valve and gas valve to the maximum rate position. Observe the linkage for any binding, loose

fasteners, or other problems that could have resulted from shipping.

3. When the actuator reaches the maximum rate position, verify that the left hand switch LS2 is held in

the 'made' position by the collar on the control rod and that the switch lever is not bottomed out

against the plastic switch housing.

4. Position the burner switch S3 to OFF. Close the control panel door and reinstall the burner front

cover. Prepare to measure the burner air box pressure by holding a rubber manometer tube tightly

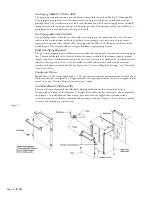

over port (4), Figure 16b. The tube must surround the hole and seal tightly against the burner

housing to measure the static pressure through the hole.

5. Position the burner switch S3 to AUTO and with the burner actuator VM1 at the maximum rate

position measure the burner air box pressure at port (4), Figure 16b. The actuator will remain at this

position for the first 20 seconds of the prepurge period. Typical static pressure readings are listed in

Table 5, Column 6. Any appreciable deviation from these values would indicate a burner air problem

that should be found before attempting to fire the burner. These problems could include linkages

disturbed during shipment, etc.