22

Circulator Blower Speed Adjustment

WARNING

To avoid personal injury or death due to electrical shock,

turn OFF power to the furnace before changing speed taps.

Furnaces are equipped with a EEM circulator blower motor.

This provides ease in adjusting blower speeds. Refer to the

Blower Performance Data in the back of the manual for prop

-

er selection of heating and cooling speeds.

To adjust the circulator blower speed, proceed as follows:

1. Motor speed Tap wiring must remain in factory position

on the control board and motor

2. There are 4 speed Tap wires to the motor T1, T2, T3, T4.

)

3. There are 5 speeds available, depending on DIP

switch settings mentioned in air flow tables for each

size furnace.

4. Cooling speed can be adjusted by adjusting S1-1, S1-

2, S1-3 (see cooling airflow Chart for reference).

5. Heating speed can be adjusted by adjusting S2-1,

S2-2 (see Heating airflow Chart).

6. Circulation / Continuous Fan speed can be adjusted by

adjusting S2-3, S2-4 (see Circulation airflow Chart).

7. Verify Proper temperature rise as outlined in the

Temperature Rise section of Startup Procedure and

Adjustment. Please refer to the tables below for dip

switch settings.

CONNECTOR ID

DESCRIPTION

CONNECTOR VOLTAGE

L

LINE, L1

LINE, L1

G

GROUND

CHASSIS GROUND

N

LINE, L2

LINE, L2

C

SIGNAL COMMON 24VAC COMMON

1

TAP 1

24VAC

2

TAP 2

24VAC

3

TAP 3

24VAC

4

TAP 4

24VAC

5

TAP 5

24VAC

Motor Tap Identification

S1-4

Min

Nom

Max

Units

ON

*

150

Seconds

OFF

100

Seconds

Heat Off Delay (S1-4)

*

= DEFAULT SETTING

This measured input must not be greater than the input indi-

cated on the unit rating plate.

5.

Turn ON gas and relight appliances turned off in step

1. Ensure all the appliances are functioning properly

and that all pilot burners are operating.

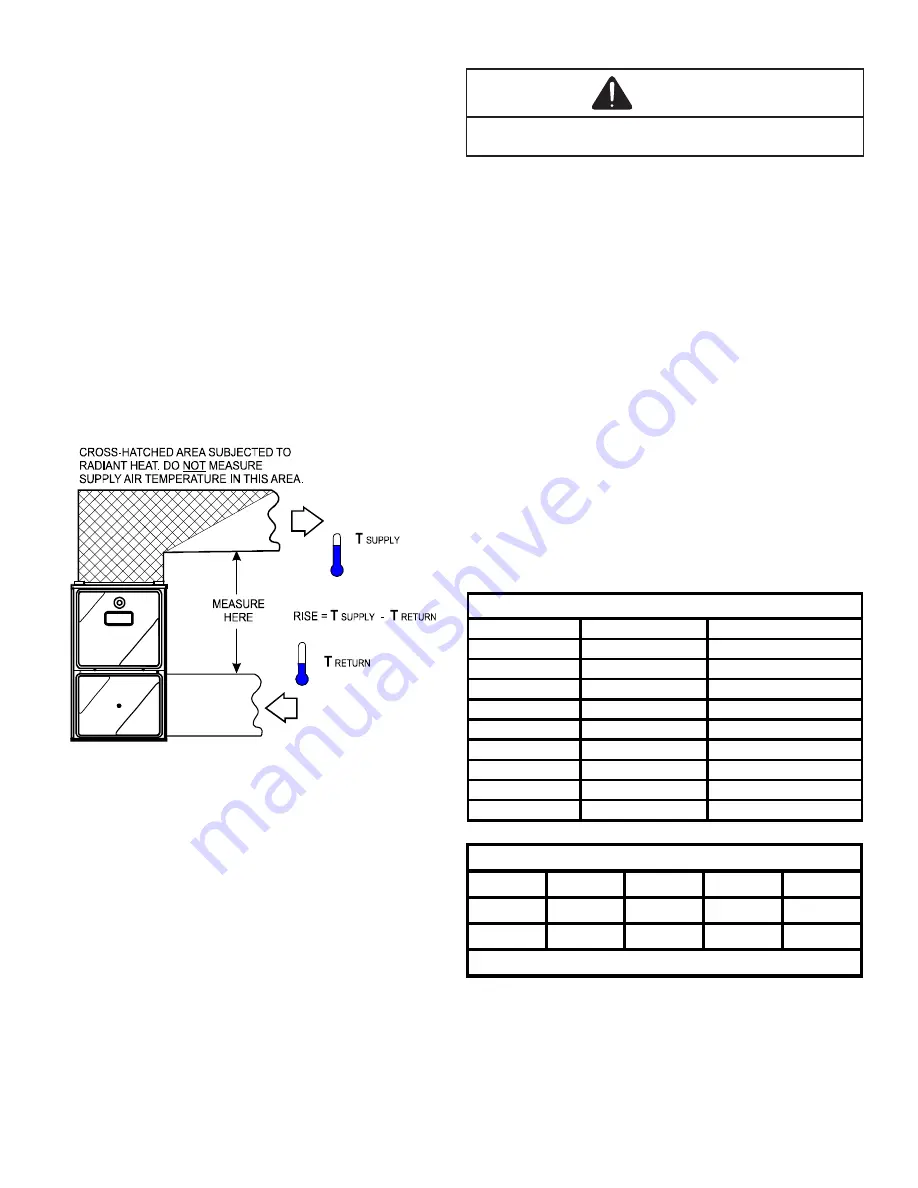

Temperature Rise

Air temperature rise is the temperature difference between

supply and return air. The proper amount of temperature rise

is usually obtained when the unit is operated at the rated in-

put with the “as shipped” blower speed. If the correct amount

of temperature rise is not obtained, it may be necessary to

change the blower speed.

An incorrect temperature rise can cause condensing in or

overheating of the heat exchanger. Determine and adjust the

temperature rise as follows. The temperature rise must be

within the range specified on the rating plate or Specification

Sheet applicable to your model.

(Please contact your dis

-

tributor or our website for the applicable Specification Sheet

referred to in this manual.)

SUPPLY

AIR

RETURN

AIR

Temperature Rise Measurement

1.

Operate furnace with burners firing approximately

15 minutes. Ensure all registers are open and all

duct dampers are in their final (fully or partially open)

position.

2. Place thermometers in the return and supply ducts as

close to the furnace as possible. Thermometers must

not be influenced by radiant heat by being able to

“see” the heat exchanger.

3. Subtract the return air temperature from the supply

air temperature to determine the air temperature rise.

Allow adequate time for thermometer readings to

stabilize.

4. Adjust temperature rise by adjusting the circulator

blower speed. Increase blower speed to reduce

temperature rise. Decrease blower speed to increase

temperature rise. Refer to the following section for

speed changing details.