Installation and Operational Instructions for

ROBA

®

-ES Couplings Type 94_._ _ _._ Sizes 14

– 65

(B.9.6.EN)

11/03/2022 TK/GH/GC/MD

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Phone: +49 8341 804-0, Fax: +49 8341 804-421

Page 19 of 29

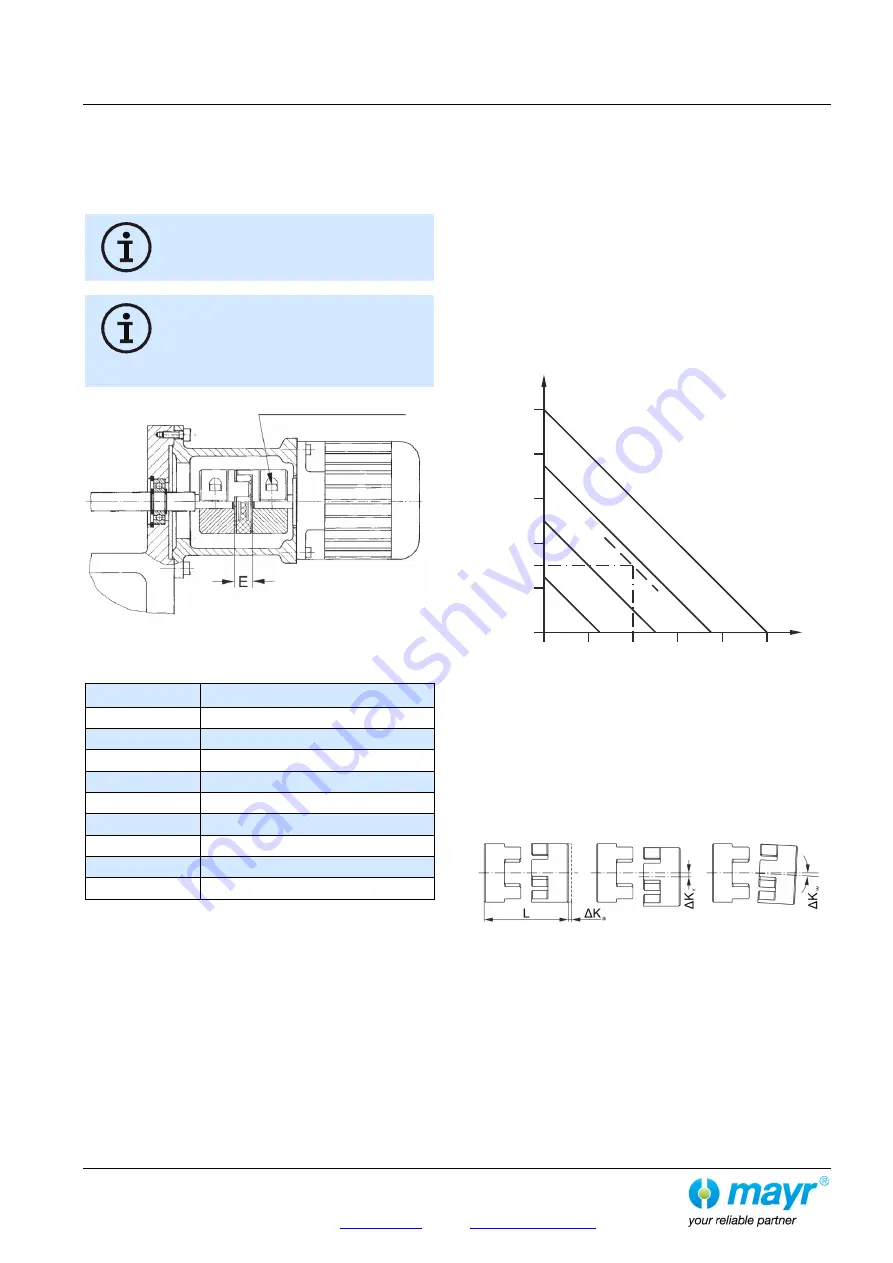

Joining Both Coupling Hubs

Due to the pre-tension on the flexible elastomeric element (6), an

axial installation force is required when joining the coupling hubs

(Figs. 2 und 3 / page 4).

The force required can be reduced by lightly greasing the

elastomeric element.

Use PU-compatible lubricants (e. g. Vaseline or

a multi-purpose grease based on mineral oil,

NLGI Class 2, with a basic oil viscosity of

approx. 200 mm

2

/s).

After joining both coupling hubs, no axial

pressure must be placed on

the

elastomeric

element (6).

Keep to distance dimension “E” acc. Fig. 15

and Table 14!

Please see guideline under ATEX!

Fig. 15

ROBA

®

-ES with clamping hubs

Table 14: Distance Dimension "E"

Size

Distance dimension “E” (Fig. 15)

14

13 mm

19

16 mm

24

18 mm

28

20 mm

38

24 mm

42

26 mm

48

28 mm

55

30 mm

65

35 mm

Coupling Alignment

Exact alignment of the coupling increases the coupling service

lifetime and reduces the load on the shaft bearings. In most of the

applications, coupling alignment using a straight edge in two

levels vertical to each other is sufficient.

However, we recommend alignment of the coupling (of the shaft

ends) using a dial gauge or laser on drives operating at very high

speeds.

Permitted Shaft Misalignments

ROBA

®

-ES couplings compensate for radial, axial and angular

shaft misalignments (Fig. 17) without losing their backlash-free

function. However, the permitted shaft misalignments indicated in

Table 10 on page 12 must not simultaneously reach their

maximum value. If more than one kind of misalignment takes

place simultaneously, they influence each other. This means that

the permitted misalignment values are dependent on one another,

see Fig. 16.

The sum total of the actual misalignments in percent of the

maximum value must not exceed 100 % (see example and Fig.

16).

The permitted misalignment values given in Table 10 refer to

coupling operation at nominal torque, an ambient temperature of

+30 °C and an operating speed of 1500 rpm. If the coupling is

operated in other or more extreme operating conditions, please

contact the manufacturers.

Fig. 16

Example:

ROBA

®

-ES, Size 24, Type 940.000.A

Axial displacement occurrence ΔK

a

= 0.56 mm equals 40 % of

the permitted maximum value ΔK

a

= 1.4 mm.

Angular misalignment occurrence ΔK

w

= 0.27° equals 30 %

of

the permitted maximum value ΔK

w

= 0.9°.

=> permitted radial misalignment ΔK

r

= 30 % of the maximum

value

ΔK

r

= 1.0

mm => ΔK

r

= 0.3 mm

Axial

Radial

Angular

displacement

misalignment

misalignment

Fig. 17

20

30

%

25

%

75

%

0%

50

%

20

40%

40

30%

60

60

80

80

100

100

Right hub shown

mirrored

Δ K

w

[%]

Angular misalignment

Δ K

a

[%] Axial displacement

Δ K

r

[%

]

Ra

d

ia

l m

is

a

lig

n

m

e

n

t