2202G1JE-DA-M-N_2010.01.

1 Safety

Reciprocating Compressor M Series

1.4 Safety Devices

1-13

Settings

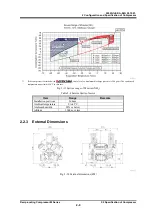

Specify the settings of Low oil pressure failure protection equipment (OP), High pressure protection

equipment (HP), and Low pressure control equipment (LP) referring to the table below, and make sure to

provide the users of this compressor with the information.

Table 1-3 Settings (example)

Compressor

failure

Compressor

enabled

Timer

Recovery

Low oil pressure failure

protection (OP)

Suction pressure

+0.10 MPa

Suction pressure

+0.12 MPa

30 seconds

Manual reset

High pressure protection

(HP)

2.7 MPaG or

lower*

―

None Manual

reset

Low pressure control (LP)

Depends on refrigerant and system in use

Automatic reset

For high pressure protection (HP), set value lower than the safety relief valve. Set the value to

protection equipment to detect an error immediately. Measure pressure electrically and generate

an alarm by a control circuit, to generate a pre-alarm when the pressure is approaching the

abnormal value.

Inspection

Method/Cycle

Each compressor’s protection equipment requires operational test and for function and accuracy. Specify the

inspection methods/cycle of respective compressor protective equipment, and make sure to provide users of

this compressor with them.

If operation test of high pressure protection equipment (HP) is performed at the

setting value, it may cause explosion of devices. Make sure to perform the test at

the normal operation pressure or below.

For operational test, use devices such as pressurize tester to check that alarms

and switches operate normally. Do not operate the compressor with all the valves

closed, or in any other dangerous conditions.

If low oil pressure failure protection (OP) or high pressure protection (HP)

shutdown the system, make sure to eliminate the cause of it before resetting the

compressor.