maxon motor

Operating Instructions

4-Q-DC Servo Control LSC 30/2

8 EMC-compliant

installation

Power supply (+V

CC

- Power Gnd)

•

No shielding normally required.

•

Star point-shaped wiring if several amplifiers are supplied by the same power supply.

Motor cable

•

No shielding normally required.

Encoder cable

•

Although the LSC 30/2 does not have a line receiver, using an encoder with a line driver is

recommended as this improves interference resistance.

•

Use cable shielding in electromagnetically harsh environment.

•

Connect shielding on both sides (LSC housing).

•

Use separate cable.

Analogue signals (Set, Tacho, Vaux)

•

No shielding normally required.

•

Use cable shielding with analogue signals with small signal level and electromagnetically

harsh environment.

•

Normally connect shielding on both sides (LSC housing). Place shielding on one side if

there are 50/60 Hz interference problems.

Digital signals (Disable, Ready)

•

No

shielding

necessary.

In practical terms, only the complete equipment, comprising all individual components

(motor, amplifier, power supply unit, EMC filter, cabling etc.) can undergo an EMC test to

ensure interference-free CE-approved operation.

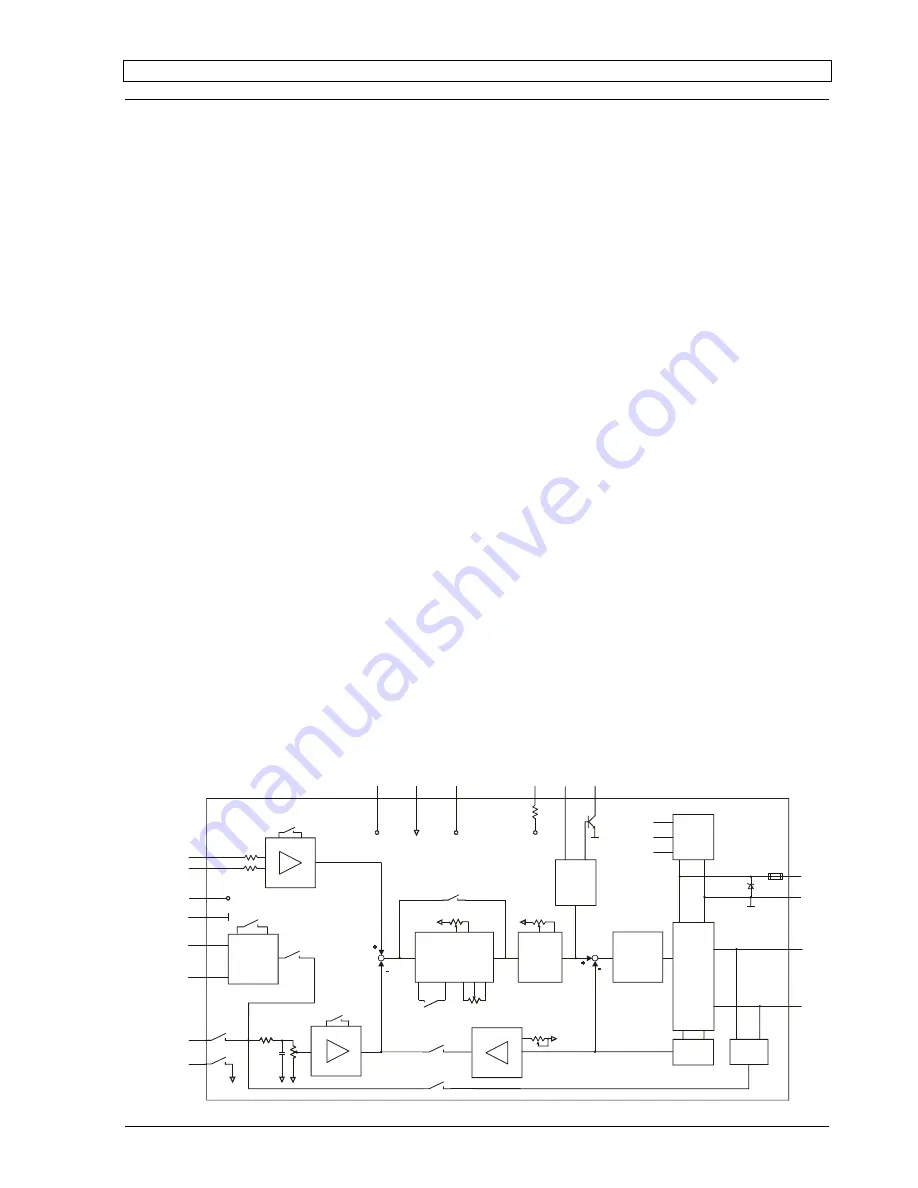

9 Block Diagram

Linear

Power

Stage

+Motor

-Motor

Gnd

+Vcc 12-30VDC

Current

Detector

Voltage

Detector

DIP6

+5V

+3.9V

-3.9V

Supply

Dis IN Ready

F/V Converter

+Venc

Gnd

Ch A

Ch B

DIP8

+5V/80mA

DIP2

DIP3

+Vcc

Dis +V

Control &

Protection

Logic

+Vaux

-Vaux

Sig Gnd

+3.9V/2mA

-3.9V/2mA

P2 IxR

P4 I max

Current

Limit

P3 Offset

DIP7

PI

Speed Control

DIP9

P5 gain

PI

Current

Control

-Set value

+Set value

DIP10

P1 n max

+Tacho

DIP5

DIP4

-Tacho

DIP1

June 2010 Edition / Subject to change

maxon motor control

13