SERVICE MANUAL

Move transmission input shaft forward

slightly and remove spacer plate

Cl7l.

Withdraw input shaft rearward from

transmission case while sliding clutch

assembly

<251

and overdrive pinion

<231

off the shaft. Inspect net>dle bearing

(20),

sealing rings

(2ll

and input shaft

for

wear or damage and renew 1f necessary.

Th

disassemble the remo,·ed Multi

Power clutch unit, place clutch assembly

on a clean bench with ove1·drive pinion

(1-

Fig.

151l

up. Push down on clutch

retainer plate

(3)

to compress return

springs, then remove snap ring

(2)

with

a narrow blade screwdriver. Remove all

components from clutch housing

(10)

and

examine for wear, scoring or other

damage. Renew clutch sealing rings

(8

and

9)

whenever clutch is disassembled.

Renew any components that show

signs of wear, damage, distortion or

overheating. Thickness of friction discs

(4)

when new is

2.41-2.59

mm

(0.095-0.102

inch). Thickness of driving

plates

(5)

when new is

1.67-1.75

mm

(0.660-0.690

inch). Fnction discs and

drive plates must be renewed as a

com

plete set.

When reinstalling piston

(7),

careful

ly compress outer seal ring

(8l

using a

feeler gage blade or similar tool while

working piston into clutch housing.

When assembling clutch plates, note

that clutch housing contains six bleed

holes (B-Fig.

152)

that are evenly spac

ed around the housing and that drive

p

l

ates have six external lugs. Install first

drive plate on lop ofpist.on with lugs

(L)

located one spline

t.o

the right (clockwise)

from bleed holes. Place the

six

piston

return springs on the lugs of the first

drive plate. Install friction discs and re

maining two drive plates alternately,

staggering the lugs of each plate one

spline further to the right. of the plate

previously installed as shown in Fig.

152.

Make certain that. return spr·ings

contact only the fir·st. plate, then install

retainer (3-Fig.

151)

and snap ring

(2).

Fig.

152-Cross-sectlonal view

of Multi-Power

clutch showing recommended method of

as

..

mbly.

Refer

to text.

8

Bleed

h

ole

L

Urove

I

URI on

tlutch

0

Clutch dii'C•

pl•t�•

To

reinstall clutch unit and input

shaft, reverse the removal procedure.

PTO LOWER SHAFT AND

DRIVE GEAR

All Models So Equipped

155.

To

remove plo lower shaft

(11

-Fig

. 153),

first

remove transmission

assembly

as

outlined in paragraph

145.

Remove clutch throwout bearing, fork

and shaft and the brake pedal

cross

shaft

from front of pto shaft. Thread two cap

screws into tapped holes in bearing re

tainer

(7)

and tighten evenly to

force

re

tainer with bearing off front of shaft.

Withdraw pto shaft rearward from

transmission housing.

Pto

drive gear

(10)

can be removed from housing after

removing mainshaft as outlined in

paragraph

152

and transmission input

shaft as outlined in paragraph

154.

To

reinstall, reverse the removal pro·

cedure. Front end of pto shaft contains

a

threaded hole that can be

used to pull

shaft into front bearing as shown in Fig.

154.

Apply nonhardening sealer to

threads of retainer and cover mounting

Paragraphs

1 55-156

Fig.

1

5

4

-

P

t

o

lower shaft

Is drll/ed and tapped at

front end for Installation

u

shown.

cap screws, then tighten to

60

>J

·

m

(45

l't.-lbs.l torque.

COUNTERSHAFT

All Models So Equipped

156.

1b

remove countershaft. 20-Fig.

153),

first

remove transmission assembly

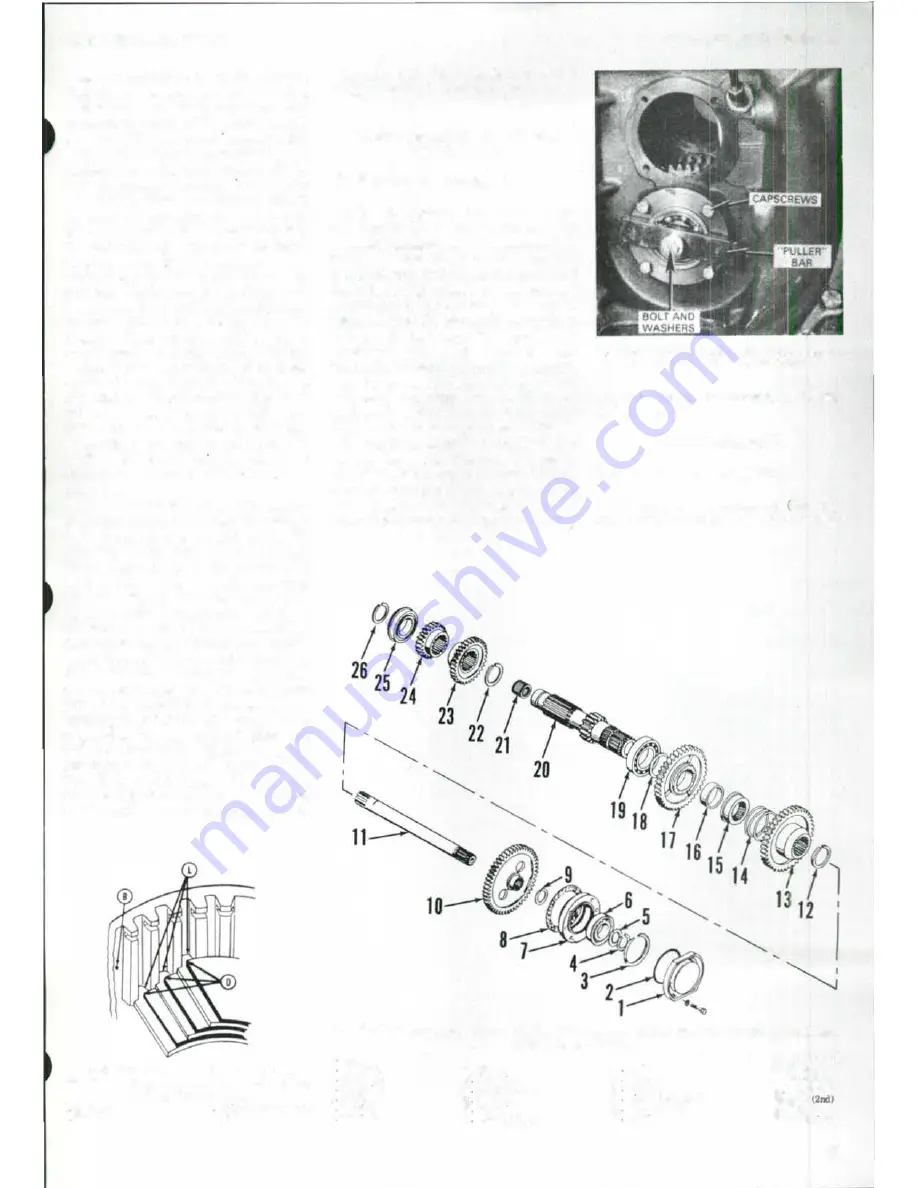

Fig. 153-Exploded view of lower

pro shaft and trantmlsslon countershalt with associated parts used

In Mu/11-Power transmission.

I

Cover

2

"0"

ring

3

Snap ring

4

Snap

nng

6 Woeher

6

Beanng

7

Re1.81ner

8. Goakel

9

Snap

nng

10 PI<> clnve

gear

II PI<>

lower

ohoJ\

12 Snap

nn11

13

Overdrive gear

14

Spnn11

16

Coupler

16

Bushing

17

Direct

d

r

i

v

e

gear

18

Thruat

wuher

19

Re8rlng

20. Count.oraiW\

21. Beanna

22. Snap

ring

23 Gear

13rcll

24.

Gear

25. Bearlna

26.

Snap nng

63