6

–

+

19

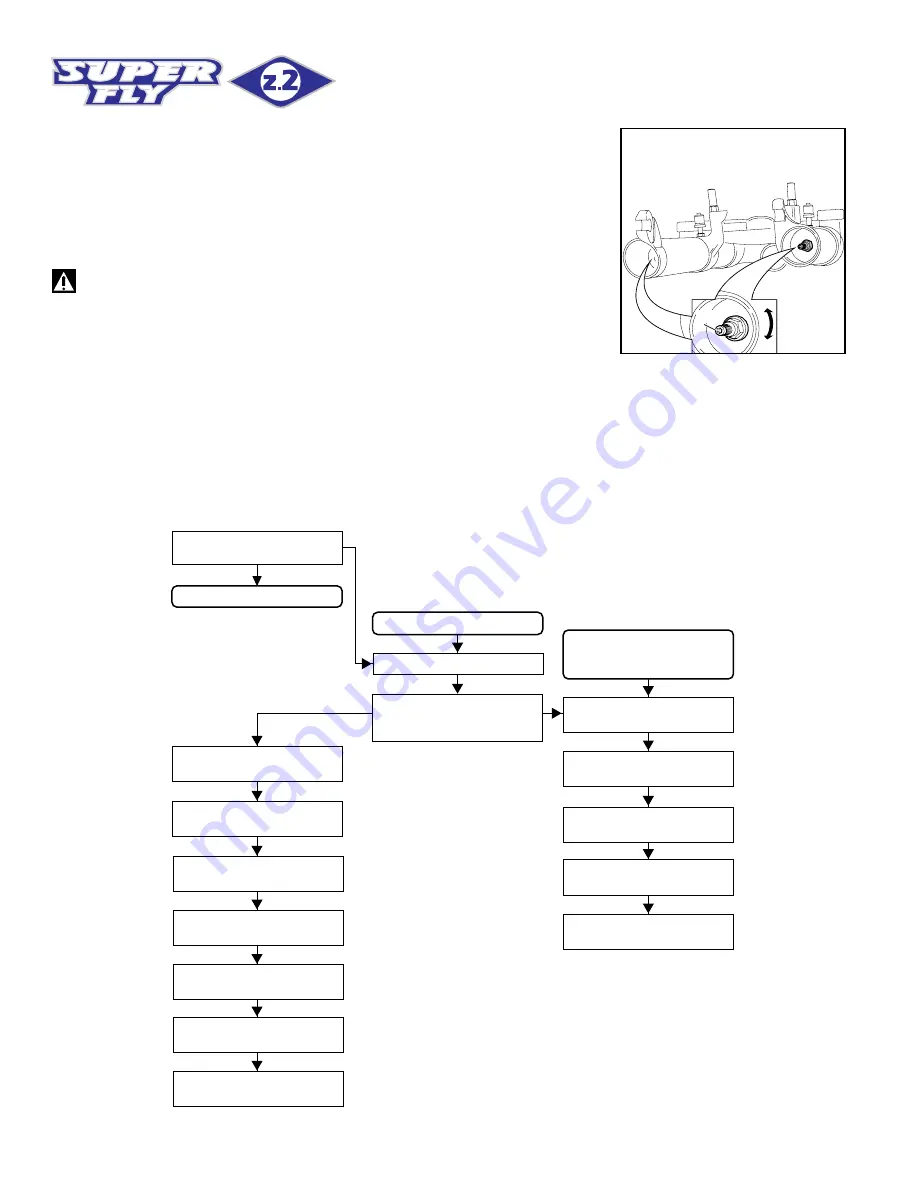

FIG. C

REBOUND ADJUSTMENT (FIG. C)

Each fork leg is equipped with an adjuster screw (19) for COMPRES-

SION and REBOUND damping. Turn the adjuster with the 2.5 mm Allen

wrench supplied with the fork. When turned, the adjuster - integral with

the inner pumping rod - will change the area in which fluid flows, thus

determining the rate of compression & rebound damping. To adjust,

always start from the minimum damping setting, i.e. with the screw fully

turned clockwise.

IMPORTANT: do not force the adjuster (19) over its limit.

DISASSEMBLY

GENERAL

– The reference numbers given in this section relate to the components shown in the fork exploded view on page 15.

– These operations refer to the fork legs having already been removed from the crown and disassembled from the brake arch.

– Before starting any operation, please read the diagram below. It shows the quickest procedure and the exact sequence in which it should be

disassembled. Locate the part you need to remove in the diagram, then look at the arrows to determine which other parts you will need to remove

first.

DISASSEMBLY DIAGRAM

PILOT BUSHING

AND SEAL ASSEMBLY

CHANGE

DUST SEAL

FIG. 5

STOP RING

FIG. 6

OIL SEAL

FIG. 7

UPPER WASHER

FIG. 8

PILOT BUSHING

FIG. 9

PUMPING ROD CHANGE

FOOT NUT FIG. 3

STANCHION TUBE WITH

WITH PUMPING ROD

FIG. 4

FOOT NUT

FIG. 1

FORK OIL CHANGE

RETAINER CUP

FIG.4

PUMPING ROD

STOP RING FIG. 11

PUMPING ROD

ASSEMBLY FIG. 12

PUMPING ROD SEALS

FIG. 13

SEAL PACK

FIG. 14

REBOUND SPRING

FIG. 14

PARKER SEALS

FIG. 15