4-7

B - HYDRAULIC ATTACHMENT AND MANUAL LOCKING DEVICE

TAKING UP AN ATTACHMENT

- Ensure that the attachment is in a position facilitating the locking to the carriage. If it is

not correctly oriented, take the necessar y precautions in order to move it safely.

- Check that the locking pin and the clip are in position in the bracket (fig. A).

- Place the lift truck with the jib fully lowered in front of and parallel to the attachment, tilt

the carriage for wards (fig. B).

- Bring the carriage under the locking tube of the attachment, slightly lift the jib, incline the

carriage backwards in order to position the attachment (fig. C).

- Lift the attachment off the ground to facilitate locking.

MANUAL LOCKING AND CONNECTION OF THE ATTACHMENT

- Take the locking pin and the clip on the bracket (fig. A) and lock the attachment (fig. D).

Do not forget to refit the clip.

- Stop the I.C. engine and keep the ignition on the lift truck.

- Release the pressure from the hydraulic circuit by pressing button 1 (fig. E) downwards

4 or 5 times.

- Connect the rapid connectors according to the logic of the attachment’s hydraulic

movements.

Make sure that the rapid connectors are clean and protect the holes which are not used, with the caps

provided.

HAND RELEASING AND DISCONNECTING THE ATTACHMENT

- Proceed in the reverse order of paragraph HAND LOCKING AND CONNECTING THE ATTACHMENT

while making sure you put back the locking pin and the clip in the bracket (fig. A).

LAYING AN ATTACHMENT

- Proceed in the reverse order of paragraph TAKING UP AN ATTACHMENT while making sure

you place the attachment flat on the ground and in closed position.

A

E

1

B

C

D

Summary of Contents for MT 1058 R PRIVILEGE

Page 1: ......

Page 3: ......

Page 4: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS...

Page 5: ...1 2...

Page 31: ...1 28...

Page 32: ...2 1 2 DESCRIPTION...

Page 33: ...2 2...

Page 44: ...2 13...

Page 74: ...2 43...

Page 78: ...3 1 3 MAINTENANCE...

Page 79: ...3 2...

Page 84: ...3 7...

Page 92: ...3 15...

Page 104: ...3 27...

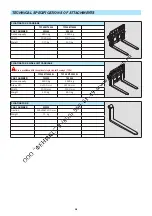

Page 116: ...4 1 4 OPTIONAL ATTACHMENTS FOR USE WITH THE RANGE...

Page 117: ...4 2...

Page 119: ...4 4...

Page 129: ...4 14...

Page 130: ...5 1 5 SPECIFIC CANADA...

Page 131: ...5 2...

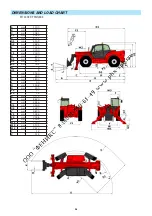

Page 132: ...5 3 TABLE OF CONTENTS DIMENSIONS AND LOAD CHART MT 1058 R PRIVILEGE 5 4...

Page 135: ...5 6...

Page 136: ...6 1 6 SPECIFIC AUSTRALIA See also the operator s manual supplement 647065 AU...

Page 137: ...6 2...

Page 139: ...6 4...