3

Smoke extract dampers - multi are shutters in the smoke exhaust piping systems. The dampers are

designed to remove heat and combustible products (e.g. smoke) from fire compartments. The

damper blade is controlled by actuating mechanism. The dampers are designed for using in fire

compartments that can be connected to the smoke exhaust ducts (tested according to EN 1366-8)

or they can be installed in or on the construction of the fire compartment.

Dampers are classified according to EN 13501-4.

General information

Classification of Dampers

Supporting

Construction

Classification

Horizontal duct system

EI 120 (h

od

- i o) S1000C

10000

HOT 400/30Mamulti

EI 120 (h

od

- i o) S1000C

10000

HOT 400/30AAmulti

Porous concrete ceiling

construction,

thickness 150 mm

EI 90 (h

ow

- i o) S1000C

10000

HOT 400/30AAmulti

Porous concrete wall

construction,

thickness 100 mm

EI 120 (v

ew

- i o) S1000C

10000

HOT 400/30AAmulti

Gypsum wall, thickness

100 mm

EI 120 (v

ew

- i o) S1000C

10000

HOT 400/30AAmulti

Vertical duct system

EI 120 (v

ed

- i o) S1000C

10000

HOT 400/30MAmulti

EI 120 (v

ed

- i o) S1000C

10000

HOT 400/30AAmulti

Assembly information

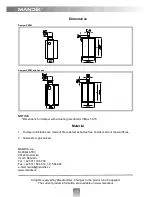

1. During installation the damper blade must be in position “CLOSED”. The damper body should

not be deformed in the course of bricking in. Once the damper built in, its blade should not grind

on the damper body during opening or closing.

3. During installation the control mechanism must be protect against damaged and pollution.

2. The installation of more dampers into the fire separating construction must meet the following

requirements:

- the minimum distance between two dampers has to be 200 mm;

- the minimum distance between damper and construction (ceiling / wall) has to be 75 mm;

In the event of fire the Smoke and Fire Ventilation System opens the damper in the affected section

which removes combustion products and heat from this section.

Fire dampers are suitable for installation in arbitrary position (axle of the blade as horizontal or

vertical). The Air Flow (smoke) must be directed from the control device side (see arrow on the

damper body).

Dampers are designed for macroclimatic areas with mild climate according to EN 60 721-3-3 zm.A2.