11

5. The adjustment of the blade can be done by connecting the power supply to the actuator (or by

the signal from the Smoke and Fire Ventilation system). The blade is adjusted to the position

"OPENED" and then back to position "CLOSED".

6. Manual operation

Any position of the damper blade can be manually set by using a special key. The functionality

of the damper can be then easily tested.

1.

Assembly, maintenance and damper check can be done only by qualified persons, i.e.

“AUTHORIZED PERSONS” that have been trained by the manufacturer.

2. All effective safety standards and directives must be observed during fire damper assembly.

3. Before entering the dampers into operation after assembly and after sequential revisions,

checks and functionality tests of all designs including operation of the electrical components

must be done. After entering into operation, these revisions must be done according to

requirement set by national regulations.

Assembly, service and revisions

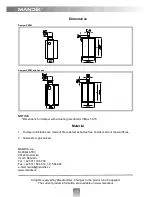

Visual inspection of proper fire damper integration, inside fire damper area, fire damper blade,

contact surfaces and silicon sealing.

4. After fire damper assembly the following checks must be carried out:

Inspection hole disassembly: release the covering lid by removing the four screws in the

corners of the inspection hole. Then remove lid from its original position.

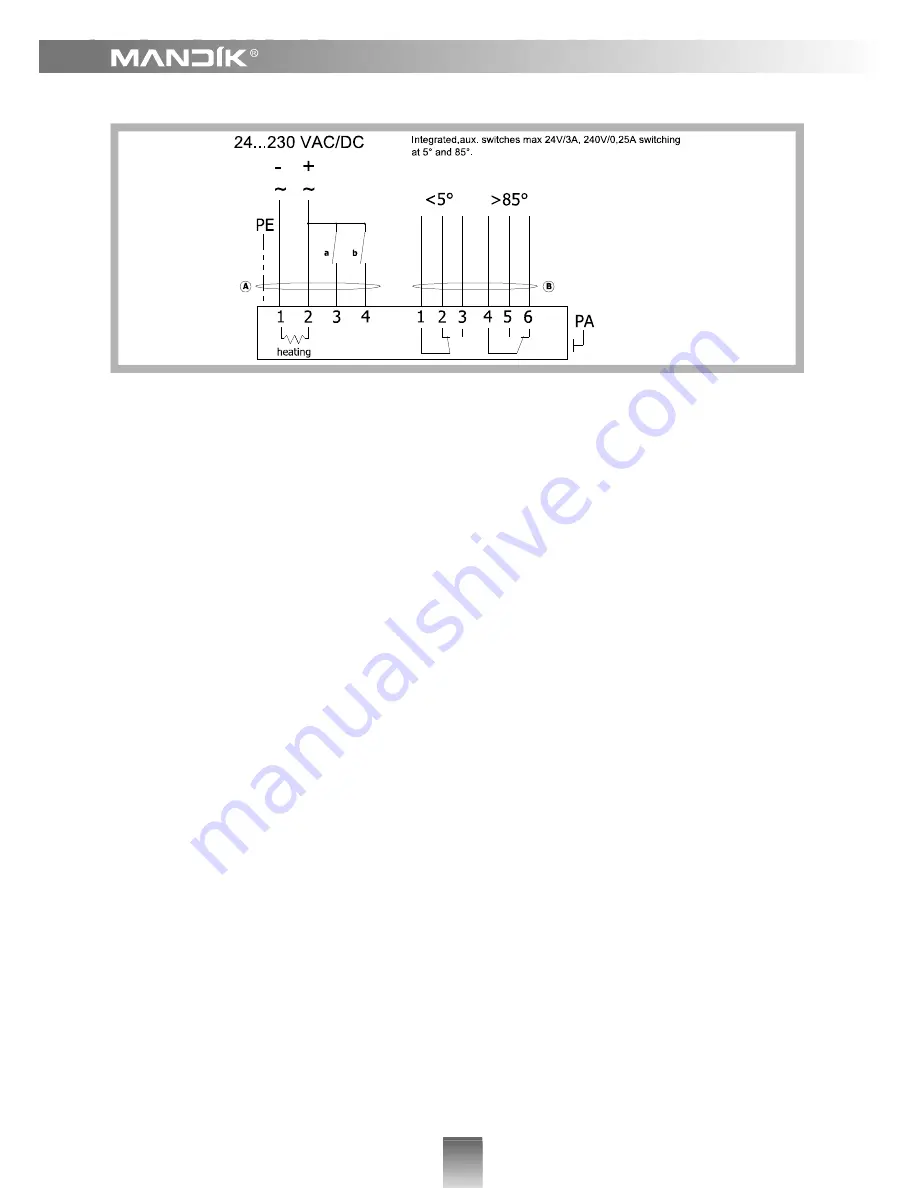

Actuating mechanism SCHISCHEK InMax 50.75-S