13

Important

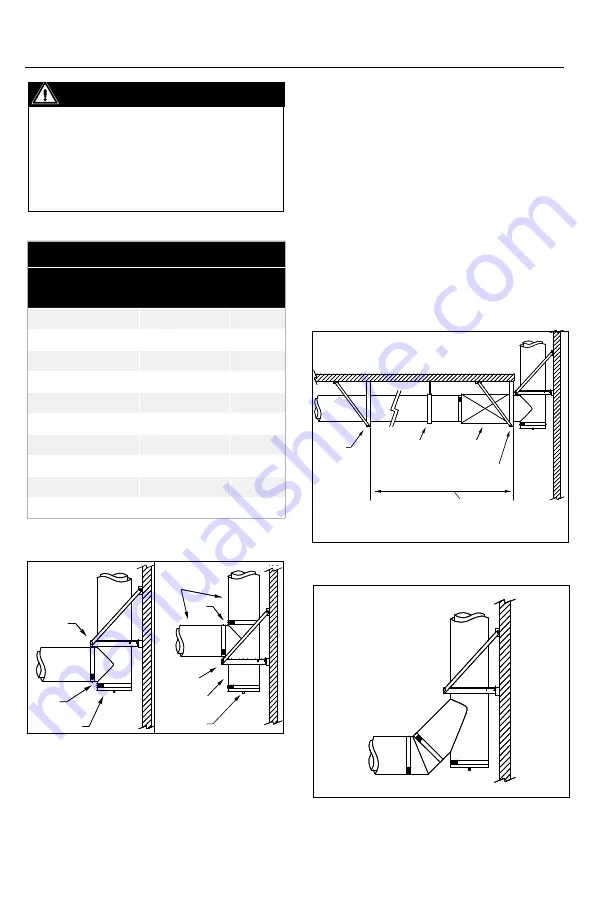

If more than 1/4” of thermal expansion is

expected between a stationary point and

the tee, the use of an expansion length

and a two axis support is recommended

to minimize bending moments on the tee

(see Figure 11 and Table 9).

Table 9

Maximum Allowable Length Between Two

Fixed Points w/o Expansion Length

Gas Temperature Rise

Maximum Length

Expansion

200

°

F

12'0''

0.25"

300

°

F

8'0''

0.25"

400

°

F

6'0''

0.25"

500

°

F

5'0''

0.25"

600

°

F

4'0''

0.25"

700

°

F

3'6''

0.25"

800

°

F

3'0''

0.25"

900

°

F

2'6''

0.25"

1000

°

F

2'0''

0.25"

Note: 60°F - 70°F ambient T°

Figure 11

Figure 12

45° tEE (t45)

1. For systems where flow resistance must

be minimized like engine or turbine exhaust.

The use of a 45° tee is suggested. It can

be combined with a 45° elbow to make a

smooth 90° turn (See Figure 12). To support

this tee, use similar method as a 90° tee.

2. When using 45° tee to connect multiple

appliances together, thermal expansion must

be considered. Thus prepared to prevent

bending moments on the tee, an expansion

length must be installed between the tees

(See Figure 13).

Figure 9

Figure 10

Wall

Support

Tee

Tee Cap or

Drain Tee Cap

Lengths

Tee

Wall

Support

Short Length

Tee Cap or

Drain Tee Cap

Stationary

Support

Suspension

Band

Expansion

Length

Stationary

Support

More than ¼" of expected

thermal expansion between two

stationary points