Assembly Notes

1. The electrical steamer shall be steadily mounted in a secure place easy for operation and maintenance

(the steamer must not be obliquely placed).

2. Don’t mount the electrical steamer and power socket in any place that might become damp or get wet

with water.

3. Do confirm if the earth electrode of the power socket is effective.

4. To move the product to another place, lift it up from the handle hole or the bottom. Handle the product

with care.

5. The facilities and objects next to the electrical steamer must be insulated.

6. It is better to mount a switch in front of the socket of the electrical

steamer, to make it easy to disconnect the power supply when the

electrical steamer is not used.

7. While the electrical steamer is working, please don’t directly touch the

inside of the steamer, in order not to be scalded.

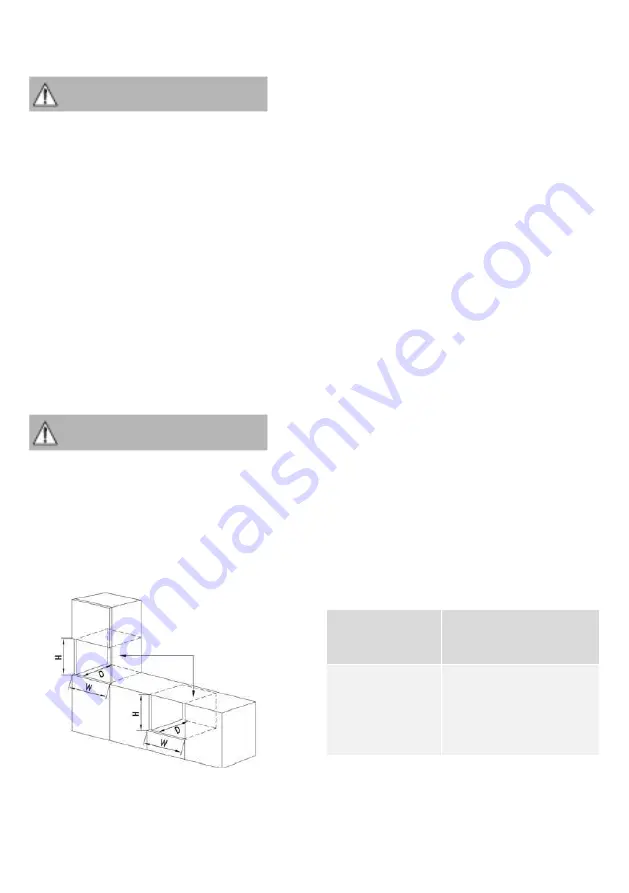

8. Mount the pre-buried electrical steamer inside the cupboard, which shall

have space for heat radiation, or else normal use of the steamer will be

affected. The cupboard shall not have a back plate. The heat radiation is

shown on the right picture:

Product Assembly Method

1. Put the machine near the mounting groove. Then, insert the power plug into the socket.

2. Lift the machine up from the bottom or the left and right clasp positions. Then, gently put the machine

down in the preleft holes in the cupboard. Next, push the machine so that it will be close to the front

panel of the cupboard in parallel, and completely embedded into the cupboard.

3. When the front door of the machine is opened, four screw holes can be seen on the rim. Fix the

machine in the cupboard with mounting screws. The machine can be fastened on the lower part of the

cupboard foundation or the upper part of the corner cabinet according to actual needs.

4. As to the detailed parameters for burying the machine in the cupboard, refer to the schematic

assembly drawing and the attached form.

Product Assembly Dimension

Type

(Electrical

Steamer)

Hole Size

MST-48CP

W564*H450*D550

(button for 5mm on

the upper part,

without buttoning on

the lower part)

6 Assembly Notes/Product Assembly Method

Please ensure certain

ventilation distance

No back plate on the back

Summary of Contents for MST-48CP

Page 1: ...INSTRUCTION MANUAL BUILT IN STEAM OVEN MODEL MST 48CP...

Page 2: ......