Malco Products, Inc., 361 Fairview Avenue, Barberton, Ohio 44203

Phone 800-253-2526 or 330-753-0361; Fax 330-753-2025 9-13-01 REV1

Page 7

MALCO XTRAX™

MODEL 1200 XTRACTOR

GENERAL INFORMATION

PUMP

The pump will prime quickly in most cases. If it does not prime after a short time, shut off the pump,

unplug the tool and attach the Empty-Out nozzle to the solution hose. With the nozzle in a bucket or

in the machine Solution Tank, turn on the pump. This should allow water to enter the pump and

machine should now be primed. Re-attach the cleaning tool when ready to clean.

PRE-HEAT / CLEAN MODE

There is only one heat setting with this machine; it is preset at the factory and is not user adjustable.

There is an interlock on the Pre-Heat / Clean Switch. When the Pre-Heat is “ON,” the solution pump

and vacuum pump(s) are inactive. To keep the cleaning solution hot while the machine is inactive, set

the solution heater on “Pre-Heat.” While the solution tank heaters work quickly, you may want to

use hot tap water to fill the tank; this will reduce the time required to heat the water to the correct

temperature.

VACUUM

Turn on the vacuum(s) when ready to clean. Make sure that the Recovery Tank dome lid is tightly in

place.

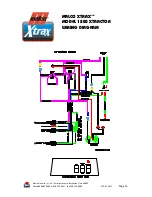

ELECTRICAL CONTROL

The Xtrax™ power cord must be plugged into a grounded (earthed) outlet with a minimum

amperage rating of 15 amps. Any other appliances that might be operating on the circuit you are

using could be using some of the power that the Xtrax™ requires and cause the breaker to overload.

As a result, a 20-amp circuit is recommended for use with the Xtrax™ Model 1200 Xtractor.

EMPTYING THE MACHINE

When you are finished cleaning, first empty the Recovery Tank by slowly pulling up on the dump

valve handle and allowing the Recovery Tank to empty into a 5-gallon bucket or floor drain. Note

that water will initially exit the machine with significant force, so care should be taken when opening

the dump valve. Next attach the empty out nozzle provided with your Xtrax™ Model 1200 in place of

the carpet wand or upholstery tool on your solution line. Turn on the pump to empty the remaining

solution in the clean Solution Tank. You should use some of this clean solution to rinse all sediment

from your Recovery Tank. You can also pump the remaining solution directly into a bucket or

wastewater receptacle. A small amount of solution will probably be remaining in the clean Solution

Tank. This small amount of solution may be vacuumed out; however, the waste tank should be

empty and the Recovery Tank lid tightly in place. It is recommended that the Recovery and Solution

Tanks be rinsed out at the end of the day with clean water and that NO chemical solutions or waste

be left standing in the tanks overnight. The vacuum lid should be left off the machine when storing to

allow air circulation in the tanks. If particles should fill the seals on the dump valve, turn the vacuum

on with lid in place and slowly close and open the dump valve a few times to dislodge them.

Remember, a well-maintained machine will provide many years of profitable service!