14

73D0129

DVKHL Series Gas Fireplace

VentInG InStaLLatIOn

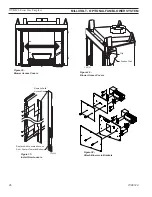

terMInatIOn cLearanceS FOr BuILDInGS wItH cOMBuStIBLe

anD nOncOMBuStIBLe exterIOrS

Figure 9 -

Allowable Venting Chart

HOw tO uSe tHe Vent GrapH

The Vent Graph should be read in conjunction with the

following vent installation instructions to determine the

relationship between the vertical and horizontal dimen-

sions of the vent system.

1. Determine the height of the center of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Sidewall Vent Graph below, locate

the point intersecting with the slanted graph line.

2. From the point of this intersection, draw a vertical line

to the bottom of the graph.

3. Select the indicated dimension, and position the fire-

place in accordance with same.

Example: If the vertical dimension from the floor of the

fireplace is 11' (3.4 m) the horizontal run to the face of

the outer wall must not exceed 16' (4.9 m).

Sidewall Vent Graph showing the relationship between

vertical and horizontal dimensions for a Direct Vent flue

system.

Figure 10 -

Rear Wall Venting Graph

Horizontal dimension from the finished outside wall

to the center of the pipe on the fireplace

V

ertical Dimension From the Floor of Unit to the Center of the

Horizontal V

ent Pipe

Dimensions in

Feet

Combustible – 6" (152 mm)

Noncombustible – 2" (51mm)

V

G

G=6" (152mm)

F

F=6" (152mm)

V

V

G

G = Combustible 24"(610mm)

Noncombustible 18"(457mm)

Combustible &

Noncombustible

H = 24" (610mm)

J = 20" (508mm)

V

H

J

C = Maximum depth of 48" (1219mm)

for alcove location

D = Minimum width for back wall of

alcove location

Combustible - 38" (965mm)

Noncombustible - 24" (610mm)

E = Clearance from corner in alcove

location

Combustible - 6" (152mm)

Noncombustible - 2" (51mm)

E

V

D

C

C

Inside Corner

Alcove Location

Outside Corner

Balcony with No Side Wall

Balcony with Perpendicular

Side Wall

FP1951

termination clearances

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

2 4 6 8 10 12 14 16 18 20

eg: A

FP2132

sidewall vent graph