MCC-35

51

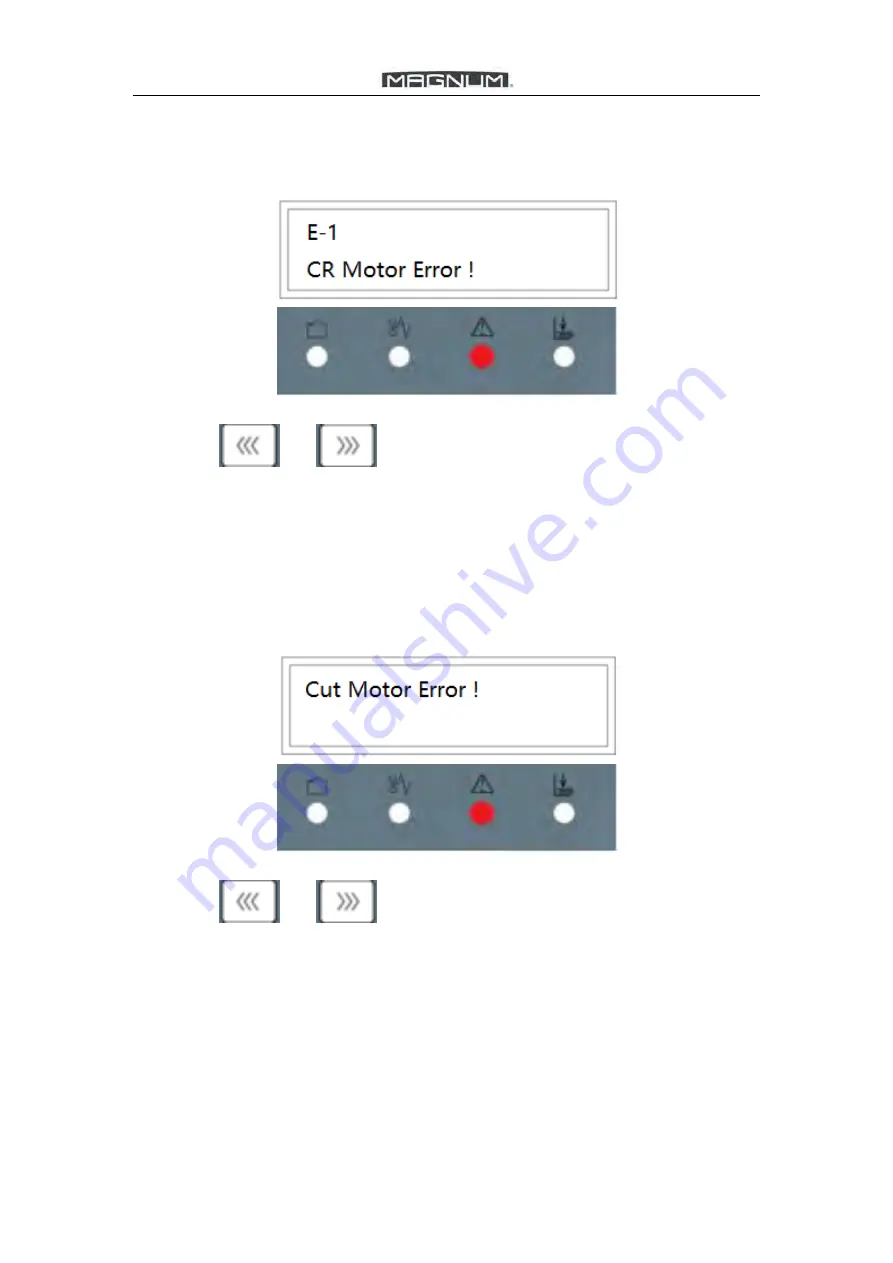

7.4 Show Error E-1

E-1 Crease Motor Error.

1. Restart the machine.

2. Press

or

to drive the jammed paper out.

3. Check if the paper is out of the spec. (100gsm~350gsm). As for crease die,

the spec. is 100~300gsm.

4. Check if CR depth is too deep and adjust it referred to

5.7.3

.

7.5 Show Error E-2

E-2 Cut Motor Error.

1. Restart the machine.

2. Press

or

to drive the jammed paper out.

3. Check if the paper is out of the spec. (100gsm~350gsm). As for crease die,

the spec. is 100~300gsm.

Summary of Contents for MCC-35

Page 36: ...MCC 35 32 Chapter 6 CUTTING FORMAT 6 1 Metric Version 6 1 1 A3 90 48...

Page 37: ...MCC 35 33 6 1 2 A3 90 50...

Page 38: ...MCC 35 34 6 1 3 A3 90 54...

Page 39: ...MCC 35 35 6 1 4 SRA3 90 48...

Page 40: ...MCC 35 36 6 1 5 SRA3 90 50...

Page 41: ...MCC 35 37 6 1 6 SRA3 90 54...

Page 42: ...MCC 35 38 6 1 7 SRA3 85 210...

Page 43: ...MCC 35 39 6 1 8 SRA3 85 210 C1...

Page 44: ...MCC 35 40 6 1 9 SRA3 90 210...

Page 45: ...MCC 35 41 6 1 10 SRA3 90 210 C1...

Page 46: ...MCC 35 42 6 1 11 SRA3 A3 C1...

Page 47: ...MCC 35 43 6 1 12 SRA3 A3 C2...

Page 48: ...MCC 35 44 6 2 Imperial Version 6 2 1 DIG 3 5 2...

Page 49: ...MCC 35 45 6 2 2 DIG 3 5 5...

Page 50: ...MCC 35 46 6 2 3 DIG 3 5 8...

Page 51: ...MCC 35 47 6 2 4 DIG 5 8...