S TYPE BANDSAW BLADE GUIDE MANUAL

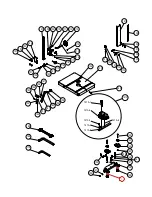

Adjust the positioning of the upper thrust bearing:

Note: Upper guide adjustment shown. Lower guides are similar. Adjusting the

bearing or block is the same procedure. The difference will be the set dimension.

1. Disconnect the saw from the power source.

2. If not already done, adjust the blade tension and

tracking.

3. Lower the blade guide assembly so that it is about

2” (50mm) above the table.

4. Loosen the set screw (A) to allow the guide block

to slide side to side.

5. Place a feeler gauge between the bearing and the

blade.

a. Guide Bearing = 0.01”-0.02" (0.25-0.5mm)

b. Ceramic Guides = 0.005”-0.007” (.127-

.177mm)

6. Slide the block up to the feeler gauge and blade

without deflecting the blade.

7. Hold the block in position and tighten the set screw

(A).

8. Repeat the steps for the other side (B).

9. Recheck the gap between the blade and the

guides taking note that the gap is equal on both sides and that the guide are not deflecting

the blade.

10.Check that the guides are behind the blade teeth 1/64”-1/32” (mm).

11. If the guides are too close or far from the teeth, loosen set screw (D) and slide the entire

guide assembly forward or aft until the front edge of the guide is within the set dimension

behind the blade teeth.

B

O

R

Summary of Contents for MI-91520

Page 1: ...OPERATING MANUAL MODEL NO MI 91520...

Page 17: ...INSTALLATION OF THE FENCE...

Page 18: ...INSTALLATION OF THE MEASURING TAPE AND POINTER...

Page 19: ...INSTALLATION OF THE RESAW GUIDE...

Page 20: ...LEVELING THE FENCE VERTICAL ADJUSTMENT OF THE FENCE 90 TO THE TABLE...

Page 21: ...ALIGNMENT OF THE FENCE PARALLEL TO THE MITER SLOT...

Page 24: ......

Page 25: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 32: ......

Page 33: ...PARTS LISTS FOR RS FENCE...

Page 34: ......

Page 35: ...MITER GAUGE FENCE JIG...