16

www.magmaweld.com

USER MANUAL | KULLANIM KILAVUZU

ID 250T DC / ID 300T DC

EN

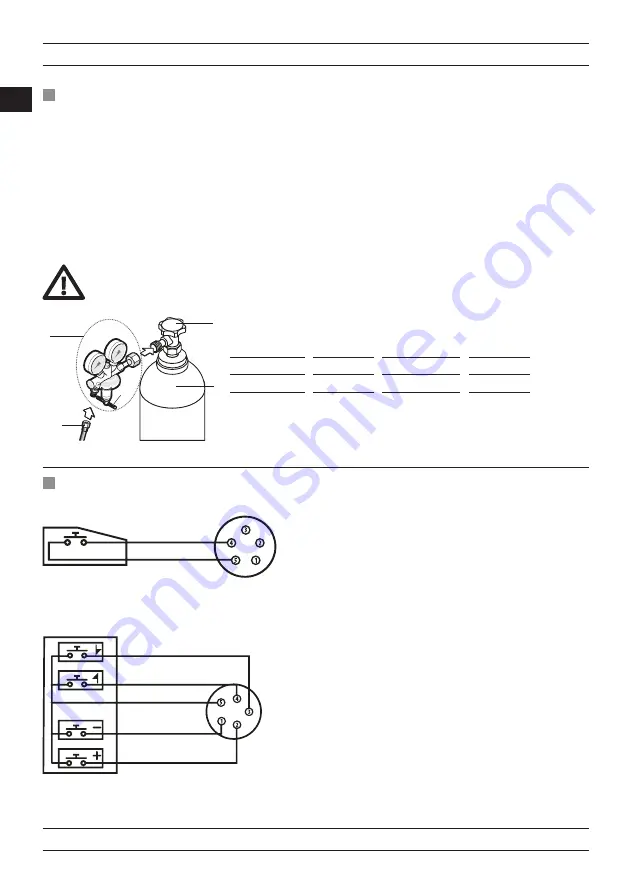

Electrode

Diameter

(mm)

Nozzle

Diameter

(mm)

Welding

Current

(ADC)

Gas Flow

(lt/sec)

1.0

1.6

6.3

9.5

30-70

30-150

6-8

6-8

• Secure the argon gas cylinder

(a)

with a chain.

• Use safe high quality regulators

(b)

and heaters approved by the standards to work safely and achieve the best

results.

• Keep the gas cylinder valve

(c)

open for a while, so that possible sediment and particles are discharged.

• Connect the gas regulator to the gas cylinder, making sure that the thread on the gas outlet of the gas cylinder

and the nut of the regulator overlap.

• Connect one end of the cylinder hose

(d)

to the gas regulator and the other end to the gas inlet at the rear of the

machine and turn on the gas cylinder valve.

• Adjust the flow rate with the flow regulating valve

(e)

.

• Make sure the connections are free of leakages.

2.5.2 Gas Connections

a

c

b

d

e

Figure 3 : Gas Connections

Installation

• TIG Torch Connection; the trigger should be connected to the control socket with the terminals

1-2-3-4-5

as

shown.

(1)

Soldering direction has been taken as the reference.

(2)

Soldering direction has been taken as the reference.

2.5.3 Trigger and Pedal System Socket Connections

• The terminals

4

and

5

must be connected to the trigger control socket.

This welding machine can carry 10/20 Liter gas cylinders. Using larger sizes may cause the

gas cylinder and welding machine to tip over. When you place the gas cylinder on the

machine, immediately fix the gas cylinder by connecting the chain. If you will not place the gas

cylinder on the machine, fasten it to the wall with a chain.