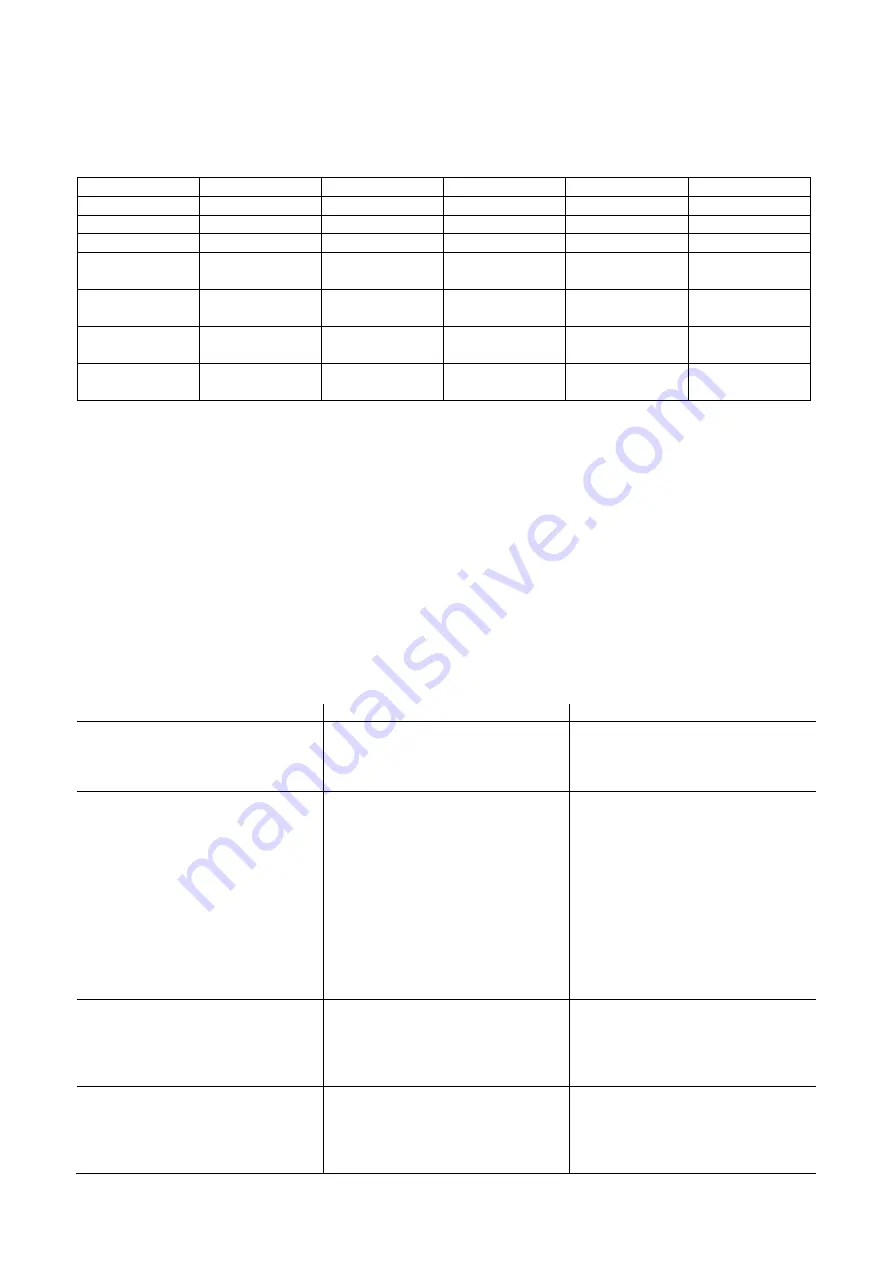

PUMP MAINTENANCE TABLE

INSPECTION

DAILY

WEEKLY

50Hrs

EVERY 500Hrs

EVERY 800Hrs

FILTERS

X

OIL

X

OIL/WATER LEAK

X

HYDRAULIC

SYSTEM

X

FIRST OIL

SUBSTITUTION

X

OIL

SUBSTITUTION

X

SEAL

SUBSTITUTION

X

14. Demolition

14.1. To allow the recycling of the raw materials, it is to separate well: pack (if supplied), the exhausted oils

and the lubricants, the electric motors, metallic pieces, parts and components in plastics.

14.2. It is compulsory to respect the norms in force related to the production, detention, harvest and disposal

of the refusals, according to what established by the legislative decree 22/97. The exhausted oils must be

delivered to the National Consortium Obligatory, while possible packing must be digested according to what

established by the title II of the legislative decree 22/97.

14.3. ATTENTION: MAER IDROPULITRICI society does not assume any responsibility for damages to

things, personal or animals, consequential and consequent to the re-use of the single parts or the single

components of the machine for function or situation of the assemblage different from the original for which

the high pressure cleaner has been conceived. Finally, when demolished, it is to destroy well the nameplate

of identification together to every other document related to the same machine.

15. Problems during the operation

Problem

Cause

Solution

The inlet hoses vibrate

Foreign piece in a valve

Air suction.

Disassemble the valve and

remove the foreign piece

Identify the source of the air

suction and eliminate it

The water does not reach the

lance although the pump is

working.

Missing water in the net.

Air inside the water circuit.

The lance nozzle is blocked.

The pump intake valve is

blocked.

The detergent intake tap is

open with empty detergent

tank.

The detergent feeder hose is

faulty.

Verify the connection with the

water supply and let the water

come in.

Bleed the circuit.

Remove and clean the nozzle.

Unscrew

the

valve

and

unblock it.

Close the tap and fill the

detergent tank.

Replace the detergent feeder

hose.

The pressure at the lance is weak

although the pump is under high

pressure.

The lance nozzle is blocked.

The pressure valve is dirty.

There is lime scale encrusted

inside

the

pressure

adjustment valve.

Remove and clean the nozzle.

Remove and clean the valve.

Remove the valve, clean it

and scale it carefully.

The motor does not switch on.

The fuses have burnt

The switch is disconnected.

The by-pass valve does not

gives electric signal to the

electronic board.

Change the fuses.

Rearm the switch.

Check the microswitch on the

valve.