11

REPAIRING THE MILLING CUTTER (plate replacement):

Keep your milling cutter sharpened at all times and without any missing carbide widia tooth.

A milling cutter with a missing or broken widia tooth will be useless within a few hours of work

and may be a potential hazard. Repair immediately.

Widia tooth replacement:

1. Use a blowtorch to remove all old widia tooth remains.

2. Use a file to make the original gap. The gap should maintain the original position

3. New plate must welded with an autogenously filler weld. It should protrude 0.5 mm above

the milling cutter (figure 7).

4. Sharpen the new widia tooth following instructions above.

MAINTAINING THE MACROZA CHASER MACHINE:

All maintenance and repair jobs on the machine must be carried out at a MACROZA Technical

Service Centre.

MACROZA Wall Chaser Maintenance

We strongly recommend that all maintenance of Macroza Wall Chasers is done at an official

Macroza Technical Service Centre.

Regular maintenance should be done to ensure the best performance of your wall chaser.

DAILY MAINTENANCE.

Check the sharpness of the milling cutter approximately after each hour of use and change the

cutter when it becomes blunt.

After each day’s use, clean the machine so that there is no dust. If necessary, blow shots of

compressed air through the machine to remove the dust.

MONTHLY MAINTENANCE.

All MACROZA Wall Chasers used on daily basis should be checked at least once a month.

It is extremely important to check if there is any play in the bearings located in the milling

cutter shaft. At the slightest play we strongly recommend that the bearings are changed.

Failure to do so may lead to severe failures in the machine engine.

In normal working conditions and due to the harsh nature of chasing job, it may be necessary

to change the bearings each month.

Look through the lateral slots of the chaser to check whether sparks produced by the carbon

brushes in the commutator are stronger than normal. If necessary replace both carbon

brushes. Always replace the pair of carbon brushes.

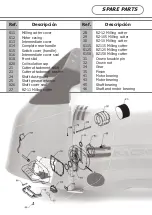

AFTER-SALES SERVICE FOR YOUR MACROZA SC100:

MACROZA has an Official Technical Service Centre network to provide you with excellent service

and fast repairs.

The use of non original MACROZA spare parts could lead to machine damage.