Pag.49

27/03/2014

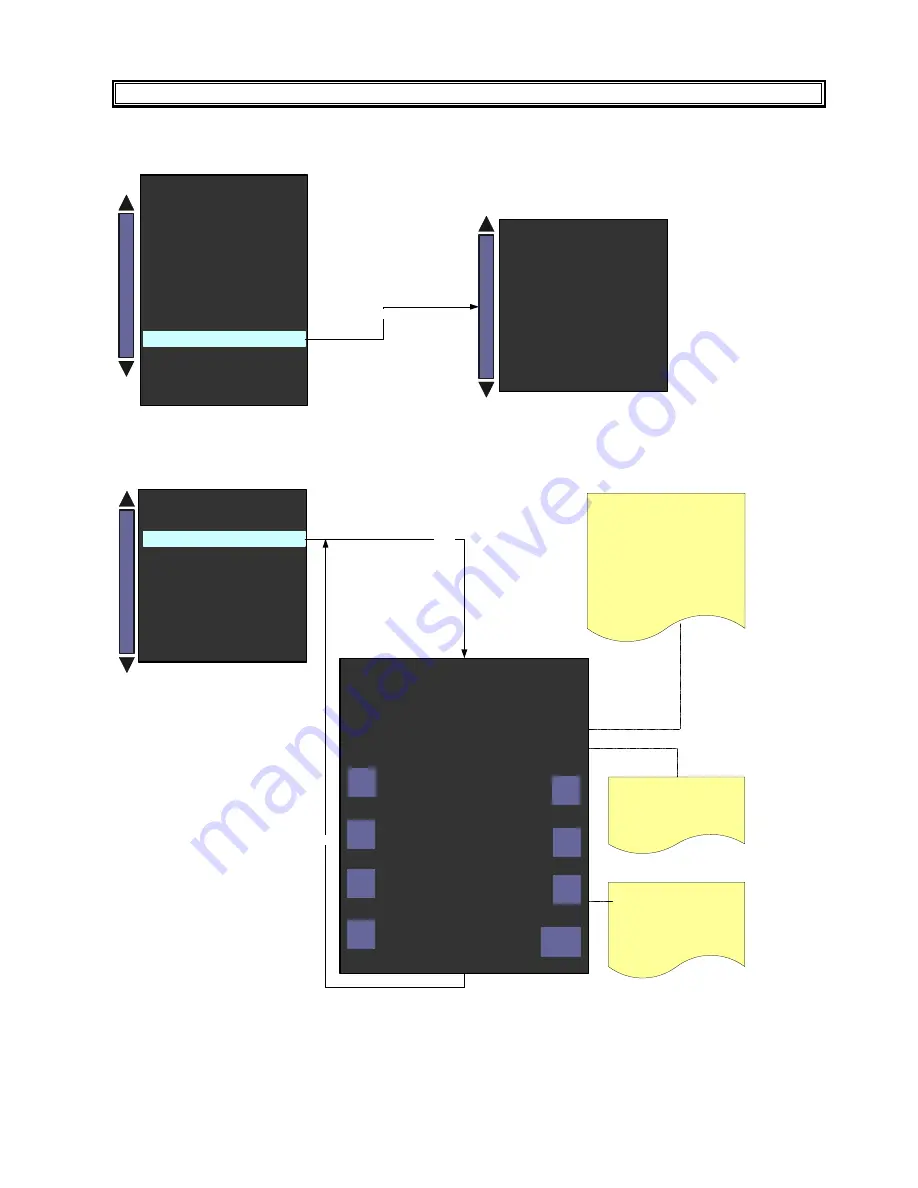

TEST ACTUATORS

System manager

-

Machine configuration

-

Machine parameters

- System clock programming

- Display regulation

- Service

- Smart card manager

- Change password

- Group manual movements

- Boiler draining

- Alarm history

- Preset configuration data

- Usb/trasponder manager

Test actuators

Test actuators

- Actuators 1

- Actuators 2

- Actuators 3

-

Milk pump

-

Mixer A

- Dispenser A

-

Mixer B

- Dispenser B

- Exhaust fan

- Electronic fan

Enter

Test actuators

- Actuators 2

- Actuators 3

-

Milk pump

-

Mixer A

- Dispenser A

-

Mixer B

- Dispenser B

- Exhaust fan

- Electronic fan

Actuators 1

Actuators 1

Enter

Test Actuators

B 1 Pump

xxxxxx

B 2 Grinder 1

xxxxxx

B 3 Grinder 2

xxxxxx

B 4 Group solen valve

xxxxxx imp. yyy

B 5 By-pass – Hot water s.v

xxxxxx

B 6 Mix Cold water for gruop

xxxxxx

People : xxcm. Yes/No

PRESS A DOSE KEYS BETWEEN B1

TO B7 TO ACTIVATE THE ACTUATOR

THAT YOU WISH TO CHECK.

PRESS THE SAME DOSE KEY TO

STOP THE ACTIVATED ACTUATOR

FROM WORKING.

THE THREE DIGITS N°. ( I

mp.yyy)

NEXT TO GROUP SOLENOID VALVE

INDICATES THE FLOW METER

COUNTING.

XXXXXX : indicate the

actuators legend and relevant

connectors on master board.

Esc

+

-

+

-

+

-

People and Cup indicate the

test for sensors : “Yes” means

that the sensors work

correctly.

L : indicates the sensor low.

H : Indicates the sensor high.

esc

1

3

5

7

2

4

6

Summary of Contents for ILC-200

Page 18: ...Pag 18 27 03 2014 INFO RESET A1 READ DOSES DATA Doses counter A B esc...

Page 19: ...Pag 19 27 03 2014 A2 READ DOSES DATA Reset doses counter A B...

Page 20: ...Pag 20 27 03 2014 B INFO RESET SYSTEM DATA...

Page 29: ...Pag 29 27 03 2014...

Page 33: ...Pag 33 27 03 2014...

Page 36: ...lb 05061 02 EN Pag 36 27 03 2014...

Page 39: ...Pag 39 27 03 2014 DISPLAY REGULATION...

Page 42: ...Pag 42 27 03 2014...

Page 43: ...Pag 43 27 03 2014...

Page 44: ...Pag 44 27 03 2014...

Page 46: ...Pag 46 27 03 2014...

Page 50: ...lb 05061 02 EN Pag 50 27 03 2014 1 1 3 3 5 5 7 7 2 2 4 6 4 6 esc esc V esc...

Page 59: ...Pag 59 27 03 2014...