6

Setting

Applications

1

cooling the hot parts

cooling the machines before changing the nozzle.

2

Drying paint and varnish

Removing stickers

Waxing and de-waxing

Drying wet timber prior to filling

Shrinking PVC wrapping and insulation tubes

Thawing frozen pipes

3

Welding plastics

Bending plastic pipes and sheets

Loosening rusted or tightly fastened nuts and bolts

Removing paint and lacquer

Soldering plumbing joints

If you are not sure about the correct setting, start with a low temperature setting

and gradually increase the temperature until you achieve optimum results

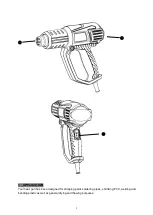

7.1 Mounting the correct accessory

(

if applicable

)

Icon

Description

Purpose

Glass protection nozzle

Protection windows when

stripping frames

Spoon reflector nozzle

Soldering pipes

Cone nozzle

Welding, shrink sleeving (heat concentrated over

small area )

Fish tail surface nozzle

Drying, thawing (heat spread over wider area )

Scraper

Stripping paint and varnish

Make sure that the tool is switched off and the nozzle has cooled down.

Falling down nozzle can set an object on fire. Nozzles must be mounted firmly and

secure on the unit.

Touching a hot nozzle can lead to serious burns .Before attaching or replacing a nozzle,