035-14527-000 REV A (599)

Form 650.77-N3U

14

Unitary Products Group

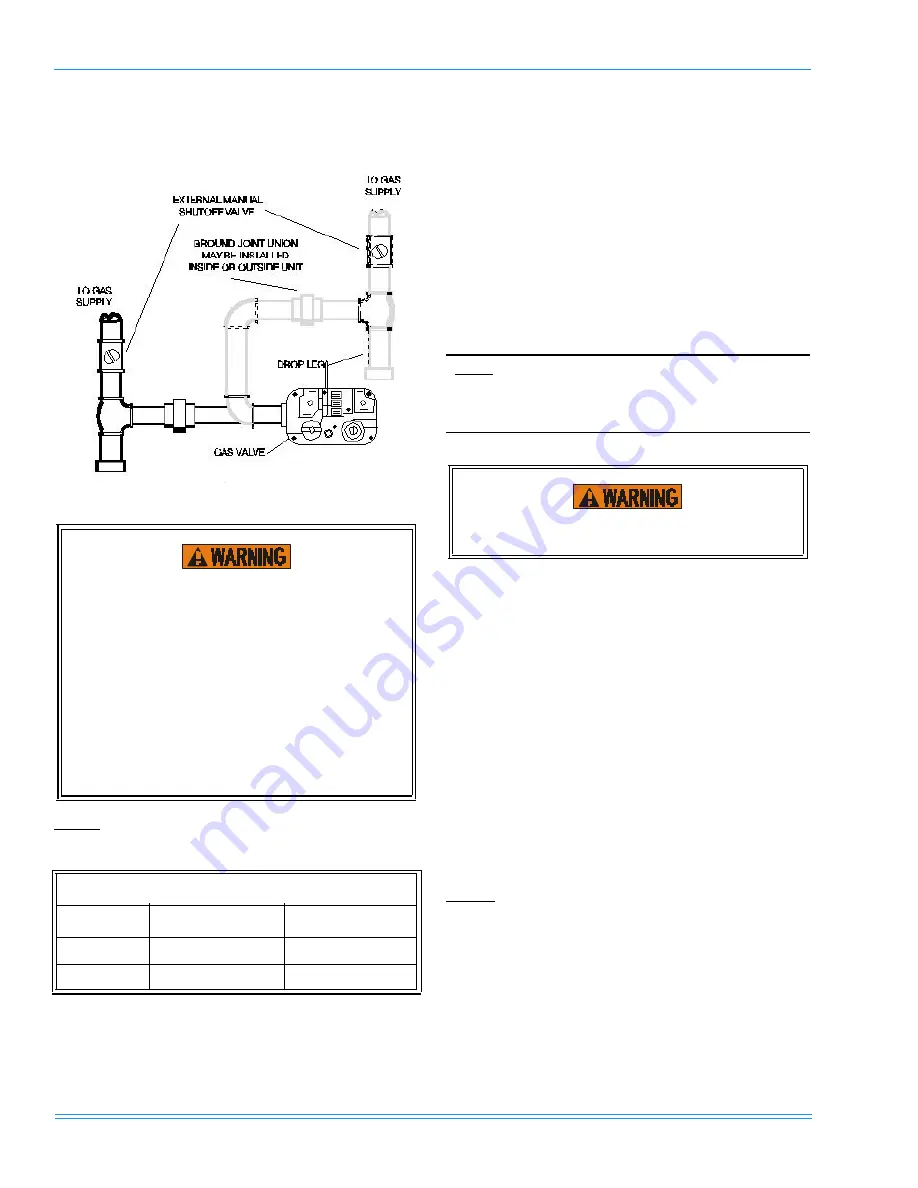

nections to the unit. Installation of a drop leg and ground

union is required. (Refer to Figure 10 on page14)

NOTE:

a 1/8” NPT plug is included in the inlet side of the gas

valve for measuring incoming gas pressure.

ELECTRICAL POWER CONNECTION

Field wiring to the unit must conform to and be grounded in

accordance with the provisions of the National Electrical

Code ANSI/NFPA No. 70 - latest edition, Canadian Electric

Code C22.1 Part 1 - (latest edition) and/or local codes. Elec-

trical wires which are field installed shall conform with the

temperature limitation for 63°F/35°C rise wire when installed

in accordance with instructions. Specific electrical data is

given on the furnace rating plate.

Provide a power supply separate from all other circuits. Install

overcurrent protection and disconnect switch per local/

national electrical codes. The switch should be reasonably

close to the unit for convenience in servicing. With the dis-

connect switch in the OFF position, check all wiring against

the unit wiring label. Also, see the wiring diagram in this

instruction.

.

Connect the power supply as shown on the unit wiring label

on the inside of the blower compartment door and Figures 11

& 12. The black furnace lead must be connected to the L1

(hot) wire from the power supply.

The white furnace lead must be connected to neutral. Also,

the green equipment ground wire must be connected to the

power supply ground.

Remove the screw retaining the wiring box. Route the power

wiring through the unit side panel with a conduit connector or

other proper connection. Make wiring connections as shown

in Figure 11 or 12. Replace the wiring box and screw.

An alternate wiring method is to use a field provided 2 x 4 box

and cover on the outside of the furnace. Route the furnace

leads into the box using a protective bushing where the wires

pass through the furnace panel.

NOTE :

The power connection leads and wiring box on

upflow units may be relocated to the left side of the furnace.

Remove the screws and cut wire tie holding excess wiring.

Reposition on the left side of the furnace and fasten using

holes provided.

ELECTRICAL CONTROL CONNECTIONS

Install the field-supplied thermostat. The thermostat instruc-

tions for wiring are packed with the thermostat. With the ther-

mostat set in the OFF position and the main electrical source

FIGURE 10 : GAS PIPING

Compounds used on threaded joints of gas piping

must be resistant to the action of liquefied petro-

leum gases.

After all gas piping connections are completed,

leak test all joints, fittings and furnace connections

with rich soap and water solution, commercial

available bubble type leak detection fluid, or other

approved means.

Do not use an open flame or other source of igni-

tion for leak testing.

INLET GAS PRESSURE RANGE

NATURAL GAS

PROPANE (LP)

Minimum

4.5 In. W.C.

11 In. W.C.

Maximum

13.8 In. W.C.

13.8 In. W.C.

Note:

The furnace’s control system depends on correct

polarity of the power supply and a proper ground connec-

tion. Refer to the furnace control diagnostics section for

symptoms of reversed power supply polarity

Use copper conductors only.