User Manual

LogicSP-2-1 / LogicSP-2-2

Page 26 of 29

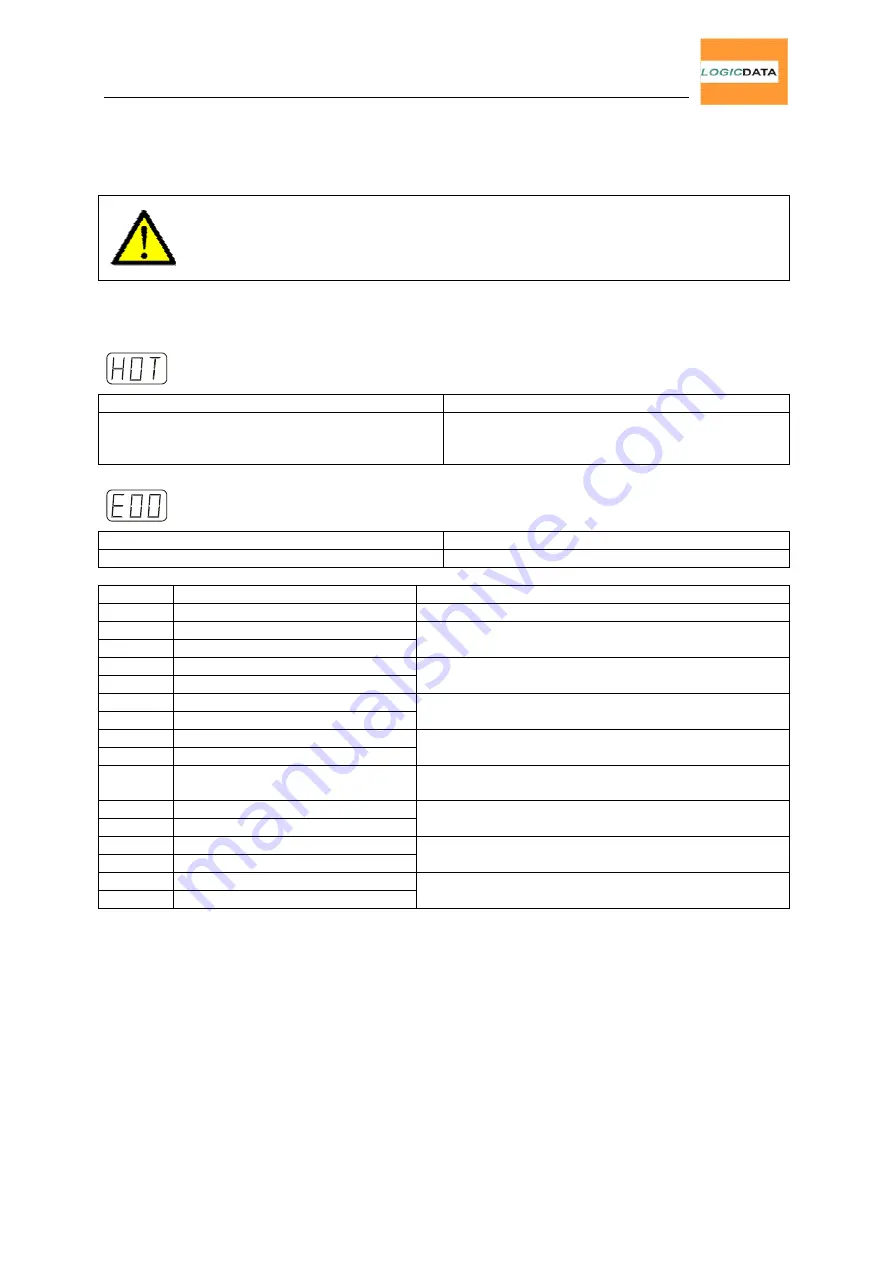

6.2. Error Messages

The LogicSP motor control can report several error conditions to a diagnostic tool (a software

program running on a PC) or directly via a handset with integrated display.

Note:

If you are not using a handset with integrated display, you will not see these error

messages.

In the absence of a handset with integrated display, these messages can be viewed

using a software program such as the LiftBox™ Diagnostic Tool by

LOGICDATA

.

The remainder of this section uses the appearance of these error messages on a standard

LOGICDATA

handset with integrated display for illustration purposes.

The display reads HOT.

Possible Cause

Solution

The LogicSP control box is equipped with over-

temperature

protection.

This

protection

mechanism forced the control box to stop.

Wait until the control box has cooled down and

the display no longer reads HOT. Then, the

control box is ready for use again.

The display reads E followed by a two-digit number.

Possible Cause

Solution

An internal error occurred.

Proceed according to the following table:

Code

Description

Solution

00

No error.

01

Relay of motor 1 is stuck.

02

Relay of motor 2 is stuck.

Unplug the control box. Contact our customer

service.

06

MOSFET of motor 1 defective.

07

MOSFET of motor 2 defective.

Unplug the control box. Contact our customer

service.

11

Motor 1 socket shorted.

12

Motor 2 socket shorted.

Unplug the control box. Remove the external short-

circuit. Plug-in the control box.

16

Motor 1 socket plug detection.

17

Motor 2 socket plug detection.

Connect a motor to the corresponding socket.

21

Oscillator defective.

Unplug the control box. Contact our customer

service.

22

Short circuit Motorwire 1.

23

Short circuit Motorwire 2.

Unplug the control box. Remove external short circuit

(exchange damaged motowire). Plug-in control box.

27

Operating Voltage too low.

28

Operating Voltage too high.

Control box cannot function with this mains voltage.

Check specifications on the type label.

29

Impulse timeout Motor 1.

30

Impulse timeout Motor 2.

Unplug control box and contact your supplier.