5

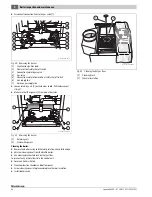

Tank installation

Logano G334X – 6 720 811 237 (2014/05)

15

Leak test

▶ Check the boiler and gas supply connections for leaks (

page 21).

Pressure tests

Disconnect the boiler and its gas shutoff valve form the gas supply pipe

system if that system is subjected to pressure tests in which the test

pressure exceeds 0.5 psi (34.5 mbar).

If the gas supply piping system is pressure-tested at a test pressure of

0.5 psi (34.5 mbar) or less, it is sufficient to disconnect the boiler from

the gas supply piping system by closing the shutoff valve.

5.7.2

Converting boiler to propane

The boiler is factory-set for operation with natural gas.

Length of the pipe in feet

(1 foot = 0.3 m)

Flow rate in cubic feet of gas per hour

1)

(1 ft

3

/h = 28.3 l/h)

1) Maximum flow rate in cu ft/hr (1 ft

3

/h = 28.3 l/h) based on a gas specific gravity of 0.60 and a gas pressure of 0.5 psi (34.5 mbar) or less and a pressure drop equivalent to

a water column of 0.3 inches (7.6 mm).

1"

1¼ "

1½ "

2"

2½ "

10

520

1060

1600

3050

4800

20

350

730

1100

2100

3300

30

285

590

890

1650

2700

40

245

500

760

1450

2300

50

215

440

670

1270

2000

75

175

360

545

1020

1650

100

160

305

480

870

1400

150

120

250

380

710

1130

Table 8 Gas pipe supply volume

Iron pipe nominal diameter [in inches]

Equivalent lengths for pipe fittings in feet (1 foot = 0.3 m)

Pipe fitting type

90° elbow

T-piece

Shutoff valve

Gas shutoff

1

3

5

0.6

1.60

1¼

4

6

0.8

2.15

1½

5

7

1.0

2.50

2

7

10

1.3

3.00

2½

8

12

1.6

3.50

Table 9 Equivalent lengths for pipe fittings

DANGER:

Risk of explosion!

Leakage from the gas pipes and gas connections may

cause an explosion.

▶ Carry out a proper leak test using leak detector fluid.

NOTICE:

Risk of system damage due to short-circuits!

▶ Cover the hazardous locations before checking for

leaks.

▶ Do not spray leak detector onto cable conduits, plugs

or electrical connection cables or allow it to drip onto

them.

Use only sealing compound that is resistant to corrosion

by liquid propane (LP) for the pipe connections. The

sealing compound must be applied sparingly to the male

thread of the pipe connections.

If you wish to convert the boiler to propane, please

contact Buderus for the required conversion kit.

Do not attempt to convert the appliance without the

approved Buderus parts and the relevant technical

documentation. The technical documentation is

included with the conversion parts.

For information about the identification of the main gas

orifice and the nominal gas orifice pressure for natural

gas and propane gas, see Chapter 2.8.3, page 7.

Summary of Contents for G334X

Page 38: ...10 Logano G334X 6 720 811 237 2014 05 38 Notes ...

Page 39: ...10 Logano G334X 6 720 811 237 2014 05 39 Notes ...

Page 40: ......