43

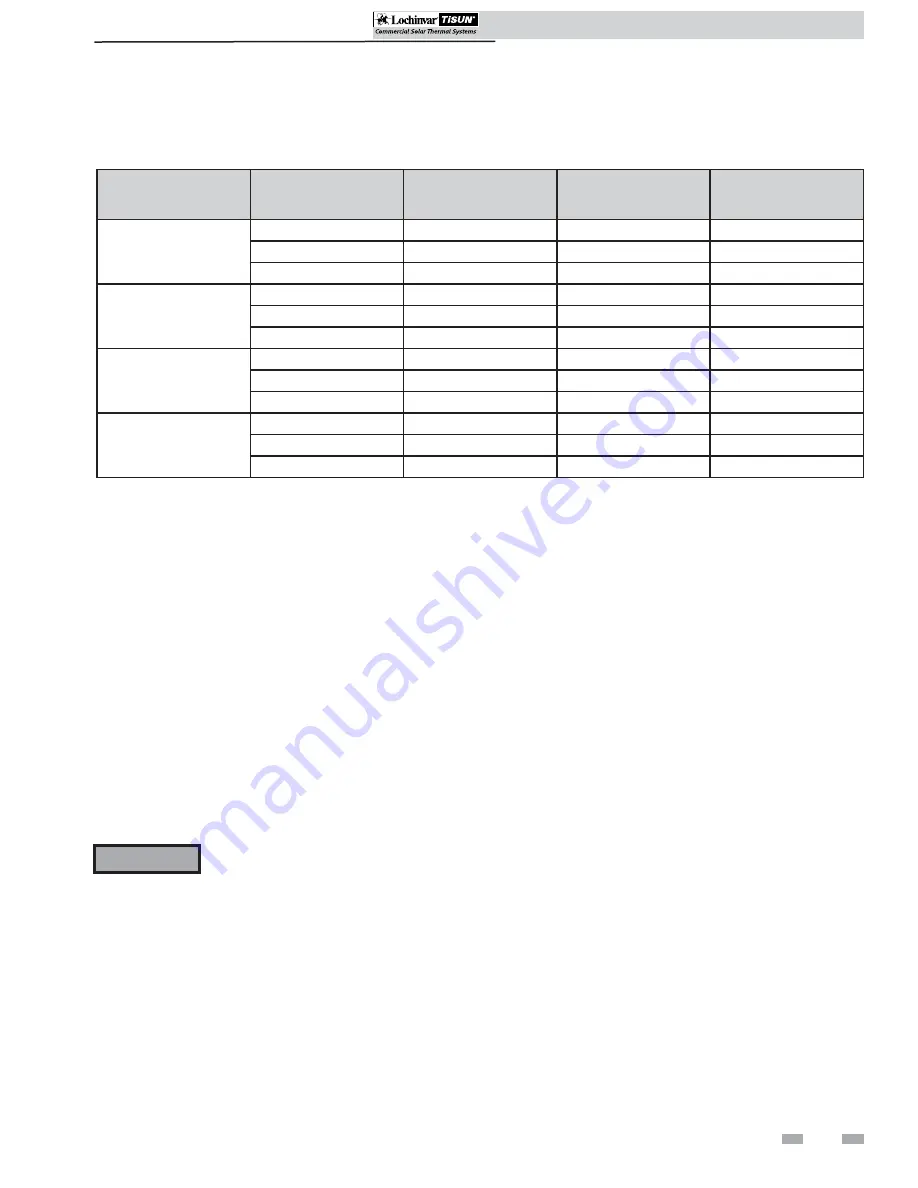

Typical properties of Aqueous So

(Glycol percentage by volume)

7

Maintenance

(continued)

Physical

Property

Temp.

°F

30% Glycol

Solution

40% Glycol

Solution

50% Glycol

Solution

Thermal

Conductivity

Btu/(hr•ft

2

)(°F/ft)

40

0.247

0.225

0.204

180

0.279

0.249

0.221

325

0.268

0.238

0.210

Specific Heat,

Btu/(lb•°F)

40

0.894

0.847

0.794

180

0.947

0.916

0.878

325

1.002

0.987

0.965

Viscosity,

Centipoise

40

5.75

9.63

14.28

180

0.68

0.85

1.08

325

0.31

0.39

0.40

Density,

(lb/ft

3

)

40

65.30

66.03

66.68

180

62.60

63.09

63.50

325

57.89

58.18

58.41

SCH Collectors Installation & Operation Manual

Solar circuit

1. Verify all system components are correctly installed

and

operational.

2. Check for leaks - inspect all water lines for signs of

leakage and correct any problems found.

3. Check System Pressure - monitor system pressure as the

circuit heats up (during testing) to ensure that the

pressure does not rise above the designed system

pressure. Excessive pressure rise indicates expansion

tank sizing or performance problems. See the expansion

tank manufacturer’s instruction manual for required

maintenance. See the expansion tank manufacturer

recommendations for sizing and pressure settings.

4. Check Relief Valve - Inspect the relief valve and lift the

lever to verify flow.

Before operating any relief valve ensure

that it is piped with its discharge in a safe

area to avoid severe scald potential.

WARNING

5. Check Freeze Protection Fluid - ensure that the heat

transfer fluid has the proper concentration of glycol as

recommended in this manual.

6. Remove any air that may have accumulated in the

system.

7. Check Flow Rate - ensure that the minimum

recommended flow rate can be achieved as described in

this

manual.

8. Visually inspect the dirt separator (if installed) and clean

if

necessary.

Collector

1. Visually inspect the collectors to ensure that they are in

proper working condition.

2. Visually inspect the collector substructure to ensure that

no components have become loose or disconnected.

3. Visually inspect the collector piping to ensure that there

are no leaks.

4. Visually inspect roof penetrations to ensure that

environmental elements can not enter the building.

5. Visually inspect the piping insulation to ensure the

proper orientation around piping.

Pump / control function

1. Check to ensure that the pump station is in working order

and creates the minimum flow recommended in this

manual.

2. Check control sensors to ensure that they are fully inserted

into the appropriate sensing well.

3. See

pump

manufacturer’s

recommendation

for

required

maintenance

procedure.

Control settings

1. Check sensor readings to ensure that the values being

displayed are accurate.

2. Check control settings to ensure that they are programmed

per the control specification.

3. See

controller

manufacturer’s

recommendations

for

the

required maintenance procedure.