8

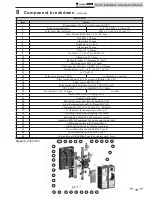

Component breakdown

20

3

2

4+5

12+15

25

8+9

22

14

11

23

16

13

26

30

27

24

4

6

17

19

1

10

18

7+9

21

SPS0250/ SPS0500

Item

Name

–

SPS0250 - Pumpstation 250 sq-ft w/ flow sensor and CU

–

SPS0500 - Pumpstation 500 sq-ft w/ flow sensor and CU

1

Solar return ball valve USA

1 1/2" x M28 x 1.5

2

Solar forw. flow ball valve USA

M28 x 1.5M28

3

Solar bleeder block M28 x 1.5 L=283mm

4

Nut M28 x 1.5mm

5

Clamp ring 22mm

6

Clamp ring 22.3 mm USA

7

Nut 1 1/2" x 16mm

8

Reducing socket 1 1/2" female x 1" male

9

Sealing kit 2x 1 1/2" ; 2x 1" ; 3x 3/4" ; 1x 1/2"

10

Solar cross piece cpl. USA

145 psi safety valve cpl.

11

Flow sensor housing 0.26-3.17 gpm cpl. w/ fill/ flush valve USA

Flow sensor housing 0.50-10.5 gpm cpl. w/ fill/flush valve USA

12

SPS0250- UPS 25/58U - 1 1/2" - 180-F12K03

115V60Hz

SPS0500- UPS 25/99U - 1 1/2" - 180-F12K09

115V 60Hz

13

Solar control unit LCD plus USA 115 Volt w/ SD-card

14

SPS0250-Sensor direct 0.26-3.17 gpm

w/ cable

SPS0500-Sensor direct 0.50-10.5 gpm

w/ cable

15

Power cord USA

w/ AC-plug XYTP

16

Control unit bracket

17

Red thermometer handle L=92mm RAL 3020

18

Blue thermometer handle L=92mm RAL 5010

19

Thermometer D51 L=100.5

0/160

°

C - 40/320

°

F

20

Wall bracket for pumpstation

250/500 sq-ft

21

Retaining clamp cropped

Spring wire 2mm

22

Sealing kit 2x 1 1/2" ; 2x 1" ; 3x 3/4" ; 1x 1/2"

23

Mounting kit S8x50/D10x50

anchors / screws

24

Insulation SPS0250 machined for pump and control unit

Insulation SPS0500 machined for pump and control unit

25

Additional insulation

D=42mm/DN32

26

Additional insulation

L=190mm machined

27

Cover white-alu RAL9006 Type C

Cover white-alu bottom RAL9006 Type B

Cover white-alu top RAL9006 Type B

28

Cover white-alu RAL9006 Type B w/ control unit cutout

12

Figure 9-1 SPS0250

SL-PS Installation & Operation Manual