6

3

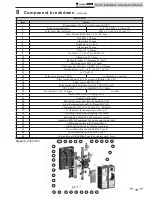

Technology, installation and commissioning

Clamp ring screw connections

■

Cut the copper pipe to length and deburr.

■

First, slide the clamp ring nut over the pipe, then slide the

clamp ring.

■

Insert the prepared pipe into the screw connection until its

stop is reached.

■

Tighten clamp ring nut by hand.

■

Use open-ended wrench to tighten clamp ring screw

connection (approx. 33 Ft lb), re-tighten if necessary.

■

When tightening the clamp ring screw connection, use two

wrenches

–

using one wrench to prevent the pumping station

from turning.

Flat seal screw connections

■

All pre-fitted solar station screw connections are firmly

tightened in the factory so that they do not need to be

retightened.

Torque levels when tightening flat seal screw connections

using AFM 34 flat seals, s = 2mm.

–

3/4" screw connection 26 Ft. lb

–

1" screw connection 40 Ft. lb

–

1 1/4" screw connection 66 Ft. lb

–

1 1/2" screw connection 96 Ft. lb

Operation, multi-function ball valve and

check valve

■

The forward flow ball valve must be open for filling, flushing

and bleeding solar systems with a filling and flushing pump.

The return ball valve should be closed.

■

Both flow checks should be opened in order to drain the

solar system (thermometer handles in 45

°

position).

■

The two mult-function ball valves must be fully open in

order to operate the solar system (turn the red and blue

thermometer handles counter-clockwise until the stop is

reached).

Figure 4-1 Forward flow multi-functioning instruments

SETTING FOR OPERATIONS,

FILLING, FLUSHING, DRAINING

FLOW CHECK CLOSED

BALL VALVE OPEN

DRAINING

FLOW CHECK OPEN

BALL VALVE 1/2 OPEN

SERVICE

BALL VALVE

CLOSED

Figure 4-2 Return multi-functioning instruments

SETTING FOR OPERATIONS

FLOW CHECK CLOSED

BALL VALVE OPEN

DRAINING

FLOW CHECK OPEN

BALL VALVE 1/2 OPEN

SERVICE, FILLING FLUSHING

BALL VALVE CLOSED

SL-PS Installation & Operation Manual