3

1

General Information

Before starting work, the Installer must read, understand and note these installation and operating

instructions.

WARNING

The solar pump station may only be installed and maintained by trained professionals. Trainees may

only work on the product under the supervision of an experienced person.

WARNING

All instructions in this Installation & Operation manual should be observed when using the solar

station. No other form of use is intended.The manufacturer is not liable for any damage resulting from

misuse of the solar station. For safety reasons, modifications or changes are not permitted.

WARNING

■

The solar station must be installed as far away from the collectors as possible. Extremely high

temperatures may occur in the pipes near the collectors. If installing in attic space, ensure that

the instruments do not overheat.

■

The pressure / temperature operating parameters must be within the prescribed limits. Excess

operating temperatures should be avoided for continuous operation.

■

The provisions stated in DIN EN 12976-1 should be observed when installing solar systems.

■

The expansion tank should be regularly checked according to DIN 4807.

■

Solar systems should be grounded to protect against lightning.

■

The system’s electrical connection for sensors and voltage supply should only be established by a

trained professional. The relevant specifications (VDE 0100, VDE 0185, VDE 0190 etc.) should

be observed as well as special local (construction) requirements. (Grey cable = tank, black cable

= collector)

■

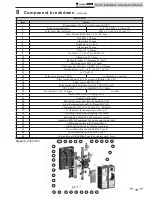

The solar pump station’s componentry varies depending on type and equipment.

■

The diagrams used are examples.

■

Subject to technical changes and further developments.

WARNING

WARNING

A properly sized expansion tank must be used to avoid damage to the solar thermal system.

WARNING

The expansion tank may be hot, ensure that scalding does not occur.

WARNING

Failure to heed these instructions, especially the safety instructions, can result in the destruction of and

defects on the expansion tank, endanger persons, and impair the operation.

WARNING

Thermal expansion tanks should be sized to account for 1.5 times the solar system circuit volume.

SL-PS Installation & Operation Manual