TIG WELDING

Before TIG welding begins, use the OUTPUT knob to set

the current to the desired preset current.

If a remote control like a foot pedal is used, the preset

current represents the maximum current with the foot

pedal depressed. For example, if the preset current is

set to 150 amps, the foot pedal will provide a range of

0-150 amps.

The CONTROL knob does nothing for TIG welding.

To make a weld, touch the tungsten to the work piece.

Only a small amount of voltage and current will be

present, so there is very little tungsten contamination.

Gently lift the tungsten away from the work with a

rocking motion. An arc will be established.

To STOP a weld, simply pull the TIG torch away from the

work. When the arc voltage reaches approximately 30

Volts the arc will go out and the machine will reset the

current to the Touch Start level.

To reinitiate the arc, retouch the tungsten to the work

and lift. Alternatively, the weld can be stopped by

releasing the Amptrol or arc start switch.

The Cross Country 300 can be used in a wide variety of

DC TIG welding applications. In general the ‘Touch Start’

feature allows contamination free starting without the

use of a Hi-frequency unit. If desired, the K930-2 TIG

Module can be used with the Cross Country 300. The

settings are for reference.

B-6

OPERATION

CROSS COUNTRY 300

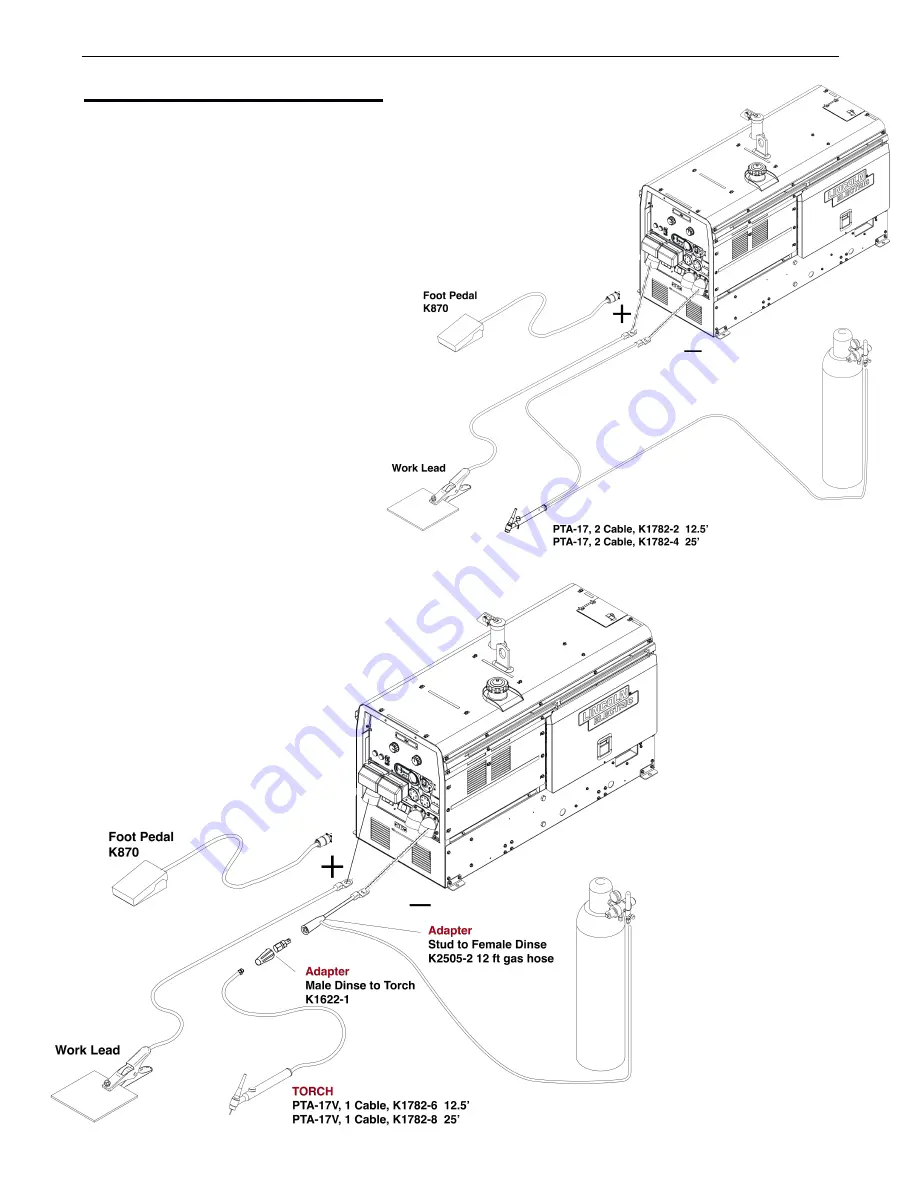

Figure B.7

TIG Setup 1-Piece Cable

Figure B.8

TIG Setup 2-Piece Cable