CAUTION

TROUBLESHOOTING AND REPAIR

F-11

F-11

VRTEX

TM

360

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely,

contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed.

Call 1-888-935-3878.

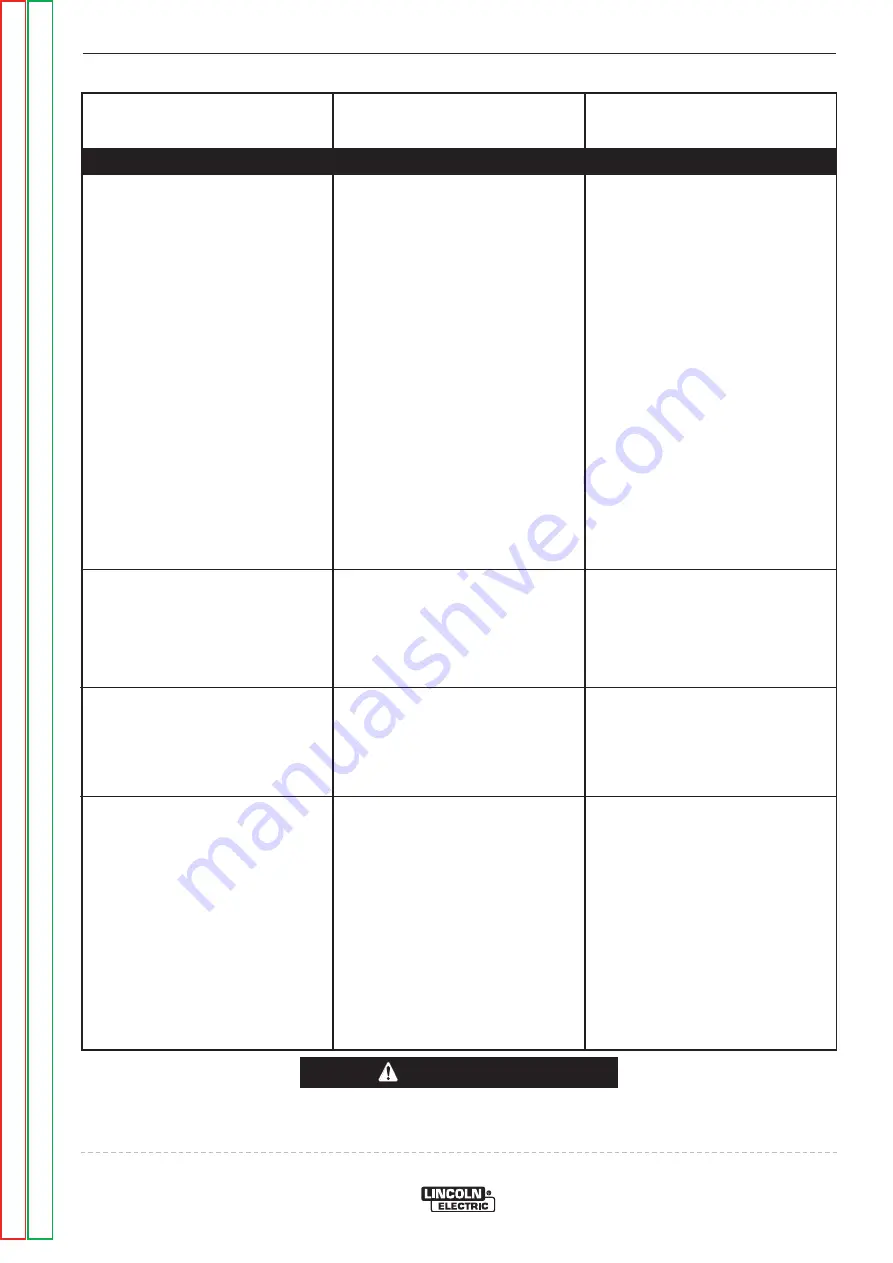

FUNCTION PROBLEMS

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

The VRTEX

TM

360 does not

function correctly in the GMAW

mode. It works correctly in the VR

SMAW (stick) mode.

Make sure the VR GMAW

Device is connected properly.

Make sure the correct welding

procedures are set.

Check for loose or faulty

connections, at the ribbon

cable, between the USB Digital

I/O Module and the terminal

block interface. Also check

between the terminal block

interface and the Relay Board.

See the wiring diagram

Check the VR GMAW trigger

connector (audio type) for a

loose or faulty connection.

Perform the

Interface Digital

Module IO Test.

The Relay PC Board may be

faulty.

The VR GMAW Device may be

faulty.

There is jitter or shaking in the

Helmet display and Monitor.

Make sure there is not any TIG

welding or high frequency

interference in the immediate

area.

Check for loose or faulty

connections between the

Helmet/Monitor and the

VRTEX

TM

360 machine. See

the wiring diagram.

The CPU constantly looses the

current time and date. At initial

boot-up the monitor reads

“CMOS” battery failed.

The internal battery in the CPU

has failed. A qualified

technician needs to address this

problem.

Perform the

CPU Removal

Procedure

. Replace the

internal battery in the CPU.

(KTS CR2032)

As viewed through the helmet and

the monitor, the entire stand

assembly appears in the middle of

the screen and the environment

does not move.

N/A

Check all cables and leads to

the Polhemus Interface

Module for loose or faulty

connections.

Perform the

Polhemus

Interface Module Test.

Return

to

Section

TOC

Return

to

Section

TOC

Return

to

Section

TOC

Return

to

Section

TOC

Return

to

Master

TOC

Return

to

Master

TOC

Return

to

Master

TOC

Return

to

Master

TOC

All manuals and user guides at all-guides.com